- Joined

- Mar 26, 2014

- Messages

- 1,491

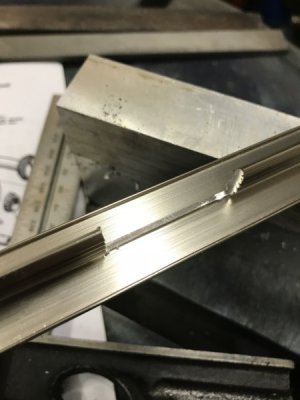

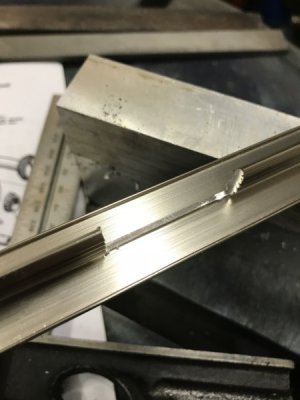

I have to mill a 1~1/4” flat spot .390” deep in a stainless .139”T moulding to bend around 90 degree corners. I have 492 pieces to mill out. I have been plunging with a 5/8” Center cutting end mill twice for each spot on my Wells Index and have 230 done.

Tonight I clamped one in the K&T and tried a 3/8” 4 flute Center cutting end mill. Plunged down and turned feed on until the correct length. I was running 860 rpm at 1-3/4” per minute feed. Seemed to work much better, but took longer.

My question is what would be the maximum feed rate? I was hoping to go up to 2-1/4” per minute? I thought 860 would be too fast? It seems to cut very well. I was using cutting oil but it cuts well with no oil also.

I can’t use a 1-1/4” end mill because the edges of the T moulding is 3/4” and it would touch the sides. Also the smaller end mill seems to cut better.

Thanks

Martin

Tonight I clamped one in the K&T and tried a 3/8” 4 flute Center cutting end mill. Plunged down and turned feed on until the correct length. I was running 860 rpm at 1-3/4” per minute feed. Seemed to work much better, but took longer.

My question is what would be the maximum feed rate? I was hoping to go up to 2-1/4” per minute? I thought 860 would be too fast? It seems to cut very well. I was using cutting oil but it cuts well with no oil also.

I can’t use a 1-1/4” end mill because the edges of the T moulding is 3/4” and it would touch the sides. Also the smaller end mill seems to cut better.

Thanks

Martin