Hi Mikey

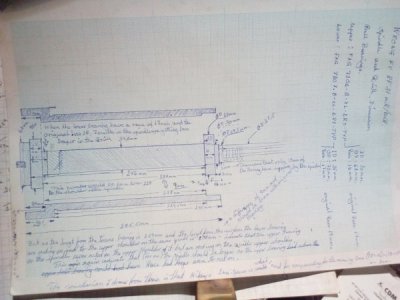

Thats exactly what I wanted to see. that was the intention with making the drawing, to give me a visualization of the relation between the quill and the spindle.

I thought it (the upper bearing) should rest on the upper shoulder on the spindle. but I was surprised to see that only 13mm. of the 16mm. race of the upper ball bearing was touching the area of 30mm. diameter surface. About 3mm of the ball bearing is above it. when the outer diameter is resting on the shoulder of the quill.

The 30mm. diameter for the upper ball bearing is 22mm. long so the ball bearing is 9mm. above the shoulder of the spindle and then the ball bearings race is 16mm wide, so it seem to me that this area on the spindle on my mill is 3mm. short. 9mm. +16mm.=25mm and I only have 22mm. I dont know if this is the same on all RF31's or if it realy make any difference, these figures are checked and rechecked several times but I get to the same measurements every time. One thing is sure and that is that it should not be any problem to press the bearings on the spindle or the quill. But one thing I think now is that I need to measure the gap between the nut and the upper ball bearing before I complete lock the spindle bearings.

I bought my mill new a year ago, and did not start use it for more than about a week ago, after a couple of cut it came intolerable noise from the quill area, I thought that the bearing was dried and that's the reason for the noise. But no the grease was fine so there is something else that caused the bearing(s) to break down I can't tell. I just have to wait till I get the new bearings and see how it all aligned and measure it to see if everything is all-right and then I am thinking about the 2mm. spacer the preset pressure, god knows what that is supposed to be? "only to be tight enough to hold it in place?

I am a beginner with mechanics, so I might go the idiot way to figure it out. so with this, no offense meant Mikey the information you gave in the description of disassembly and assembly is good, but I just need to go this way to assure myself and I like making these drawings

, and I'm not of english origin (Norwegian berserk) so it's take some time to formulate and use the right terminology, both English and mechanical.

knut