-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spindle woes pt. 2.

- Thread starter Izzy

- Start date

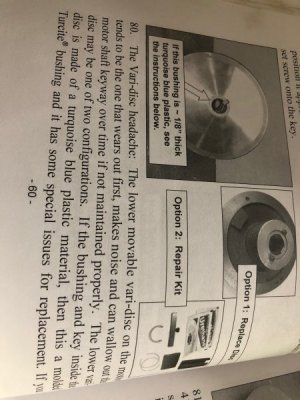

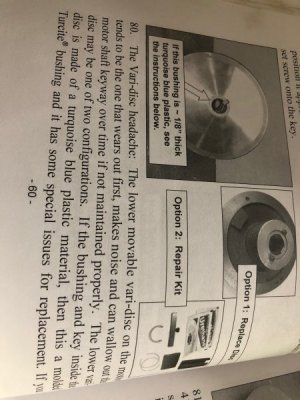

Izzy do you know if you have delrin bushings on both of the cone pulleys the ones that slides up/down on shaft?I was told that these are the main problems with Bridgeport but mine is the Series 1 so I don't know if series 2 has these plastic bushings.Maybe this is the problem why the belt is somewhat loss and slips.

If you can get access to the variable pulley I would try checking for play on the shaft to pulley. If the bushing is worn it will cause the pulley to chatter and wobble giving a lot of noise. As for your speeds that is determined by the variable pulley. If the bushing is shot it will not have the movement that’s designed. Also you drive belt could be stretched causing you to not get those lower speeds.

To check your spindle get rid of the collet and put your indicator on the inside of the spindle. Check it in two areas preferably one on taper and one on the straight part. That will give you true spindle runout.

9out of 10 times your noise is gonna be from the variable pulley.

To check your spindle get rid of the collet and put your indicator on the inside of the spindle. Check it in two areas preferably one on taper and one on the straight part. That will give you true spindle runout.

9out of 10 times your noise is gonna be from the variable pulley.

Pulley thats at the front and slides up/down mine has two black bushings that is glued in place with epoxy.The other pulley that has the spring on it and also slides up/down has a different type of bushing but looks to be plastic or some kind of fiber,but its also epoxy in place which is what I am working on now.The pic shows the pulley and old parts.Yours could be different than mine which all this is a new experience for me which is another reason why following along.The book is for a Series 1 I know yours is different series # but maybe this help

Last edited:

You know a person hates to take anything apart when the mind has a big ? in it.You will have to remove the motor which at that time you be able to see if the pulley wiggles that has the bushings in it.If it does I believe that it be a safe bet that the other bushings for the vari pulley will also be bad.But you may also discover even bigger problem.Say if it is the pulley on the motor is loose and wiggles then there's chance that the motor shaft may also be damage if the problem has been going on far to long.But lets be optimistic and say that only the plastic bushings are bad.But like others it could also be bearings which I had to replace one and it was 30.00.Anyway I went to H&W website which sells parts for these BP which some parts are price far while others will test a person pacemaker.So while there I look up what I think is your mill and it looks like you also have plastic bushings.So take a look at H&W Series II 4hp see if this looks like your mill vari parts.

Last edited: