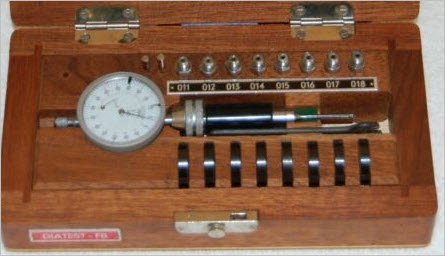

Been doing some tire kicking on these. I seem to be encountering more applications where they would be useful. But quite spendy, even used.

Long-winded question. Some sets include ring standards (usually for a lot more money). Other sets do not. How does this work normally? I assume you screw in a split ball anvil size, then pre-register to the matching ring gage. So do you always 'zero' the dial to a particular gage ring standard & now you are measuring +/- deviation to that ring size? Example zero to a 0.2500" gage, measurement reads +0.0015, so bore = 0.2515"

Or does one move the dial face to equate to the ring gage value & indicator becomes an actual measuring device? Example 0.1250 ring gage, dial set to read 0.100 on little hand plus 0.025" on the dial. Now a measurement dial reading of 0.0265" means 0.1265"

Reason I'm asking - are bore gages sizes to an appropriate split ball sizes & one manufacturer may be different than another. In all honesty I was going to get one without gage rings & set the split lap to my 10ths reading digital micrometer. The mic isn't an independent standard like a ring but I guess as accurate as I can work to for OD parts anyways. Thoughts?

Long-winded question. Some sets include ring standards (usually for a lot more money). Other sets do not. How does this work normally? I assume you screw in a split ball anvil size, then pre-register to the matching ring gage. So do you always 'zero' the dial to a particular gage ring standard & now you are measuring +/- deviation to that ring size? Example zero to a 0.2500" gage, measurement reads +0.0015, so bore = 0.2515"

Or does one move the dial face to equate to the ring gage value & indicator becomes an actual measuring device? Example 0.1250 ring gage, dial set to read 0.100 on little hand plus 0.025" on the dial. Now a measurement dial reading of 0.0265" means 0.1265"

Reason I'm asking - are bore gages sizes to an appropriate split ball sizes & one manufacturer may be different than another. In all honesty I was going to get one without gage rings & set the split lap to my 10ths reading digital micrometer. The mic isn't an independent standard like a ring but I guess as accurate as I can work to for OD parts anyways. Thoughts?