- Joined

- Dec 21, 2018

- Messages

- 48

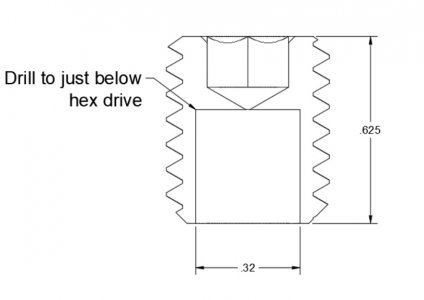

I have made a couple of these in the past. I recently made another one for larger taps. My originals were 1/2" diameter, and the center drilled end of the follower would only go up to about a 5/16" tap since it was so small. I made the new one 5/8" a diameter body and the follower portion is 5/16", allowing for bigger taps. I've attached the prints and models, as well as the McMaster part numbers for the spring and set screw. The set screw just needs a hole drilled into it. McMaster didn't have a long enough spring, so the set screw goes down over the follower inside the body, to put pressure on the spring and still allow the follower its full range of motion.

I used A2 tool steel and hardened, but another kind of steel may be used

McMaster spring 9657K389

McMaster set screw 94105A708

I used A2 tool steel and hardened, but another kind of steel may be used

McMaster spring 9657K389

McMaster set screw 94105A708