Hi All

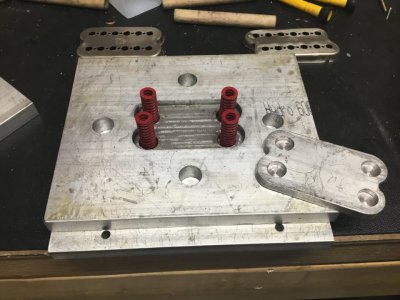

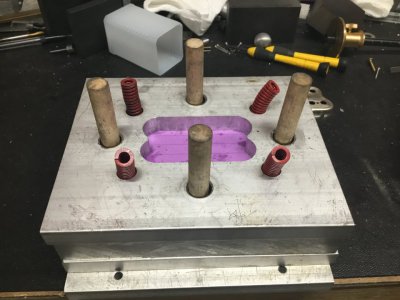

I have to buy lots of these 10mm x 30mm medium load springs because after pressing just one pickup cover the springs lose their original shape and don't bounce back, (as you can see in the pic). Do I need to go to a heavier load spring or is there a better alternative? I don't want to have to re-make all my die plates as they took forever to mill.

Any and all help and advice is greatly appreciated.

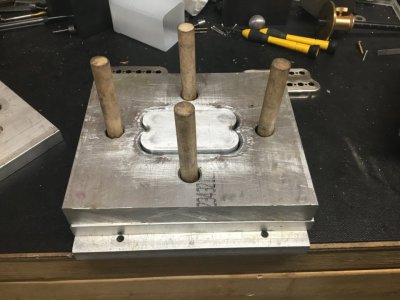

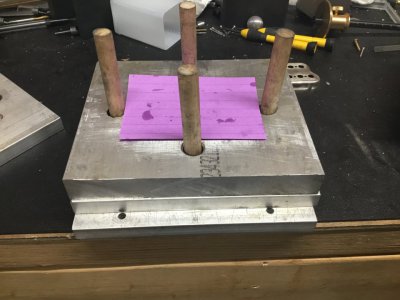

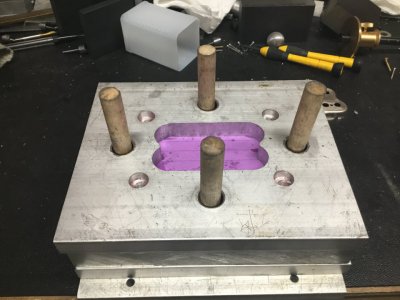

(Picture showing just the top two plates of my die jig.)

I have to buy lots of these 10mm x 30mm medium load springs because after pressing just one pickup cover the springs lose their original shape and don't bounce back, (as you can see in the pic). Do I need to go to a heavier load spring or is there a better alternative? I don't want to have to re-make all my die plates as they took forever to mill.

Any and all help and advice is greatly appreciated.

(Picture showing just the top two plates of my die jig.)