- Joined

- Jan 28, 2011

- Messages

- 3,484

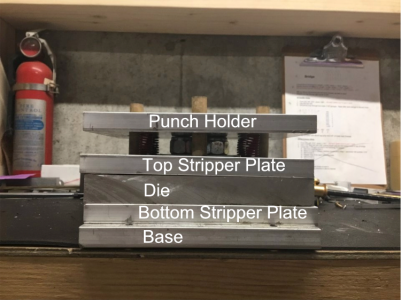

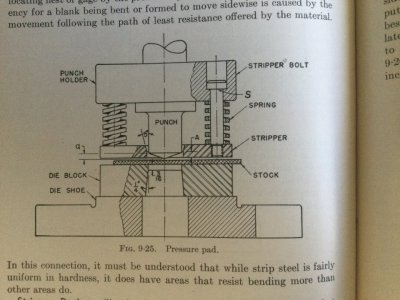

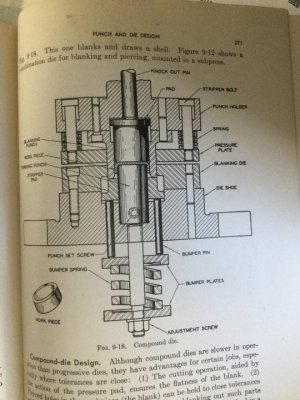

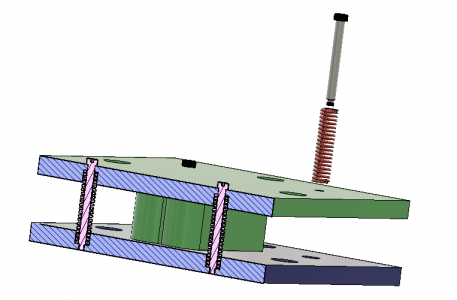

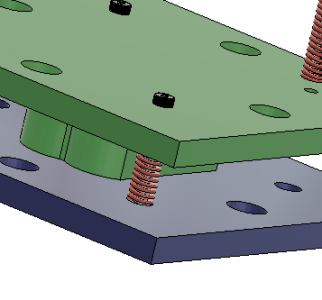

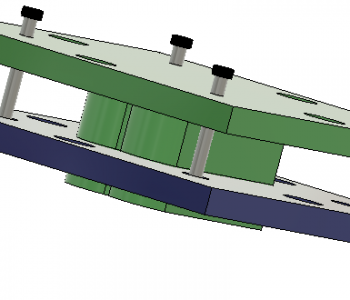

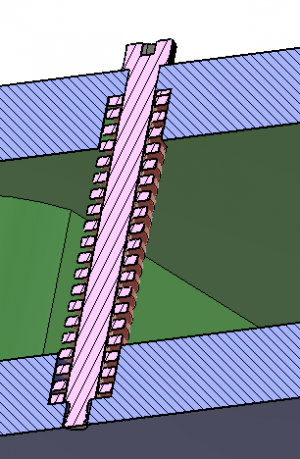

We stamp lots of thin strip materials, no drawing jobs. We build our dies with 4 of 3/4” diameter OD 3/8” ID Green die springs 1 1/2” long with a collapsed height of 1 1/4” for the stripper plate and use ejector pins usually 4 to push the knock out to push the part out.

www.mscdirect.com

www.mscdirect.com