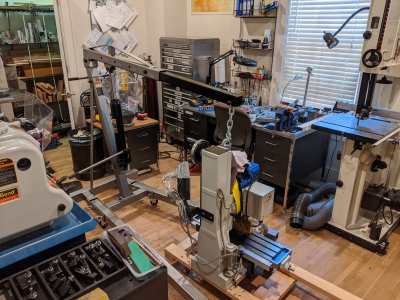

I have some comments on the mill so far but I will update this thread as I get familiar with the mill.

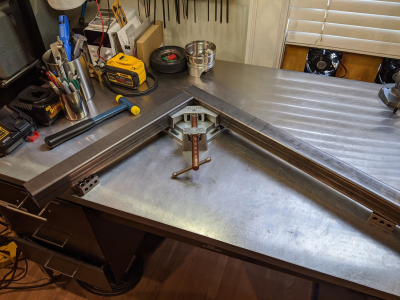

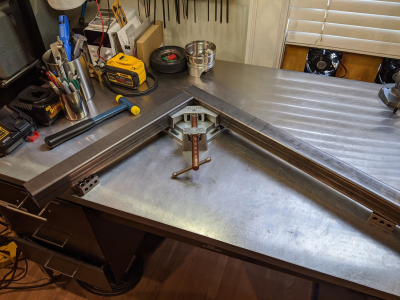

The table and X/Y axis movements seem very smooth and precise. Back lash is about .003 out of the box. The Z axis is also fine.

The quill is another story. The lever downfeed feels rough, like a cheap drill press. The fine feed is obviously not machined correctly since it binds at a certain degree of rotation. Seems like the worm gear is drilled off center. That is very disappointing. Not sure if it is fixable. I reality I don't think I will use the fine feed much but for $4K I expected more.

Maybe I am being picky but there are several annoying issues with the electronics: The quill DRO automatically turns on when you move the quill but has no auto-off. So if you happen to bump the quill handle the display will come on and stay on until the battery is dead. That is a silly design at best. I want to know the guy who thought auto-on without an auto -off was a good idea. My battery is almost dead already and I haven't used the mill.

Also, when you power the machine off normally, the circuit board begins to beep to alarm you that power has been lost. Duh. This might be helpful on a production machine that is on all day but when I turn my mill off I don't expect 9-10 warning beeps! WTF! I am pretty sure the piezo speaker on that board is coming off very shortly. That's a shame because it will also beep for over-temp or over-current so I will lose that capability and probably void the warranty. Is this engineering really that hard? Seriously?

Robert