-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starting on a one shot oil manifold

- Thread starter Aukai

- Start date

- Joined

- Feb 2, 2013

- Messages

- 3,627

watching!

- Joined

- Oct 4, 2016

- Messages

- 7,012

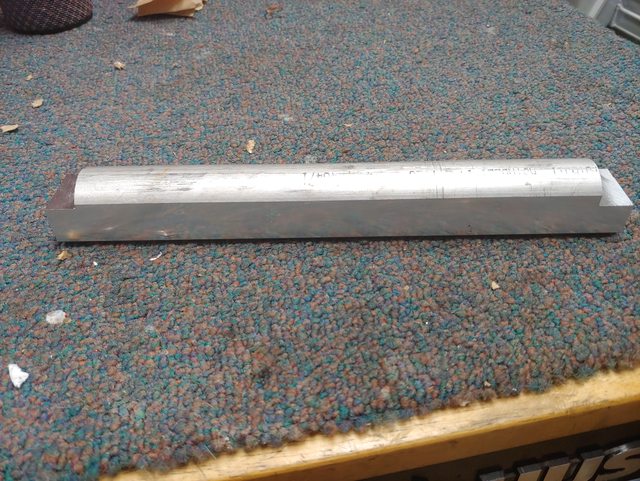

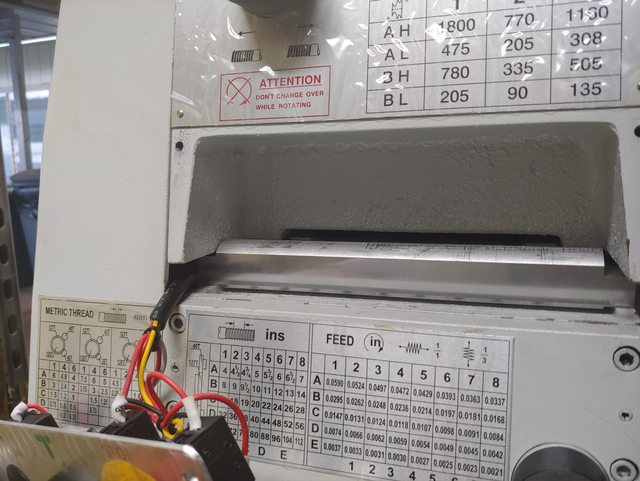

The Norton box has 15 drip oil holes where the bar is located, and one of the most popular modifications is the one shot system. The original has one hole on the side that you shoot oil into, and it randomly finds the holes to lubricate the gears, and shaft bearings. It also just drips oil all over the drip pan because it is not an enclosed system, drip oiling. I have a temporary/permanent catch tray that will give me HACK ROYALTY status till I get bothered enough to change it.

- Joined

- Jun 12, 2014

- Messages

- 4,808

You do not need an inline check valve, there is one in the Bijur pump. They sell various right angle 1/8NPT to 4mm tube fittings through some on-line specialty sites (see below on eBay) and also Acer ( supramachinetool on eBay). They do have one way check/metering valves, I have found them not necessary in this application. I have used aluminum 4mm tubing for the distribution to the holes, I use a wire stripper cutter <> which seems not to crush the tube, I use metal epoxy but you could thread them also. Alternative is using brass manifold and soldering in copper or brass tubes, or as David does making a full distribution aluminum manifold. Lots of examples posted.

Fitting Pipe NPT 1/8" Male X Compression 4 mm OD Tube Tubing 90 Deg Elbow | eBay

Fitting Pipe NPT 1/8" Male to Compression 4 mm OD Tube 90 Deg Elbow Brass. End A: Pipe NPT 1/8" Male. 90 Degree Elbow.

www.ebay.com

Fitting Compression 4mm OD Tube to Pipe 1/8" Male NPT 90 Elbow Swivel Rotating | eBay

Fitting Compression 4mm or 5/32" OD Tube X 1/8" Male NPT 90 Elbow Swivel Rotating 360. Male End: 1/8”NPT. Compression End: 4mm OD Tube. 90 Degree Elbow. Rotating 360 Degree on the Thread.

www.ebay.com

Aluminum Pipe (4mm) for Lube System $15/10ft Bijur | eBay

Aluminum Pipe (4mm). Part #: Aluminum Pipe-4. Orders under 150 lbs. Orders above 150 lbs. Piscataway, NJ 08854.

www.ebay.com

4mm OD 5' COPPER LUBRICATION PLUMBING PIPE TUBING COIL Showa Bijur 73100-31 | eBay

Ideal for most plumbing applications in bathrooms, kitchens and lubrication systems. Copper pipe or tubing may be sent with a 'raw' shear cut ends, this may reduce the workable size of the pipe by ¼” or so.

www.ebay.com