-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steady Rest

- Thread starter woodchucker

- Start date

- Joined

- Nov 25, 2015

- Messages

- 8,284

yes it squeaked, but no it's not magnetic. I just cleaned out the chip tray.. used a magnet to pick out the ferrous stuff so I can separate the brass.Doesn't sound like brass, sounds like Ampco bronze (aluminum bronze) to me. Did it squeak when you tapped it? Ampco bronze has excellent wear resistance, but may not be soft enough for this application. It has some iron content, so the chips are slightly magnetic.

so if it is Ampco bronze, too hard for a tip? Not enough of a bearing surface? Any other indicator.

- Joined

- Nov 25, 2015

- Messages

- 8,284

BTW if anyone is interested:

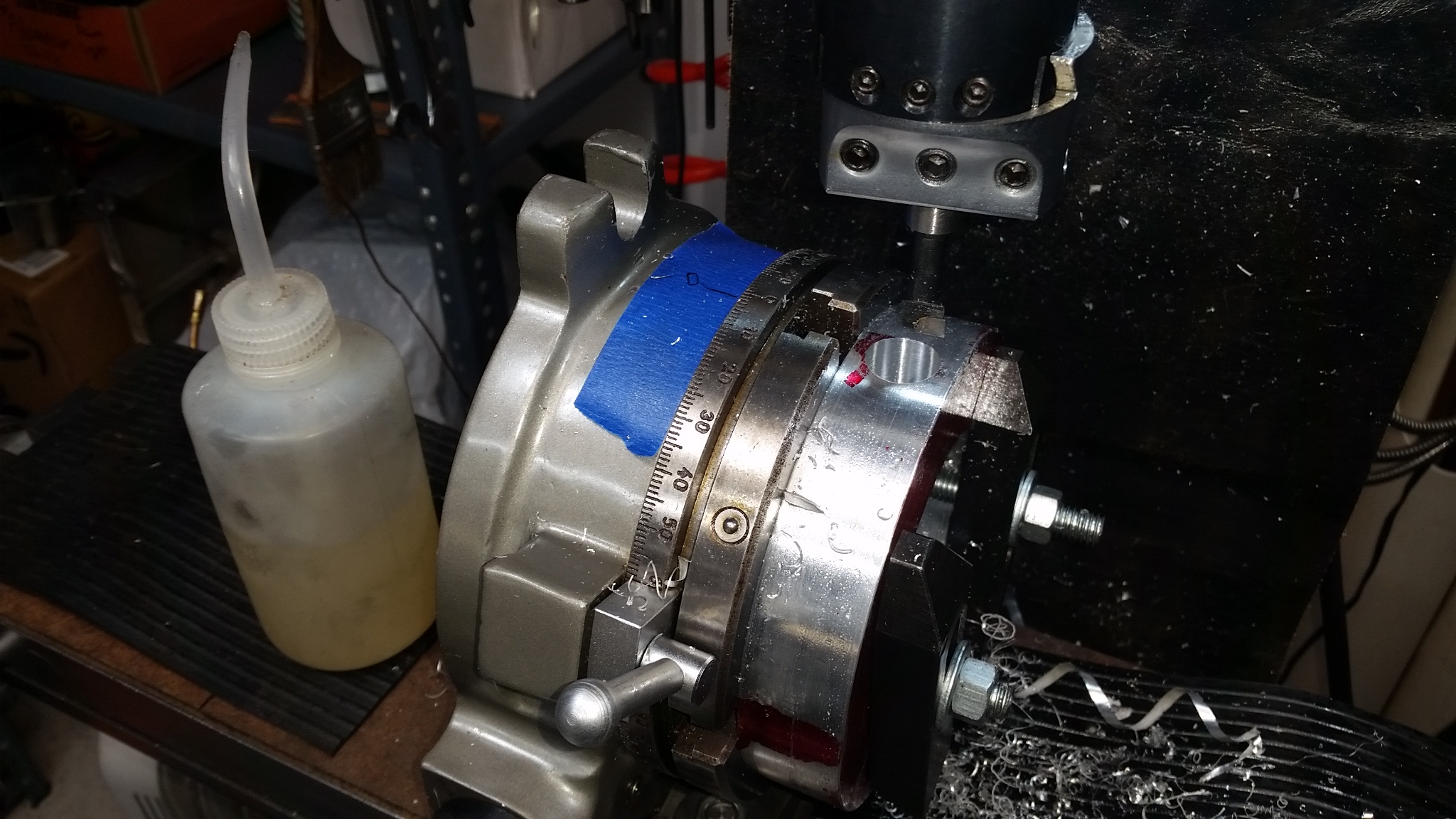

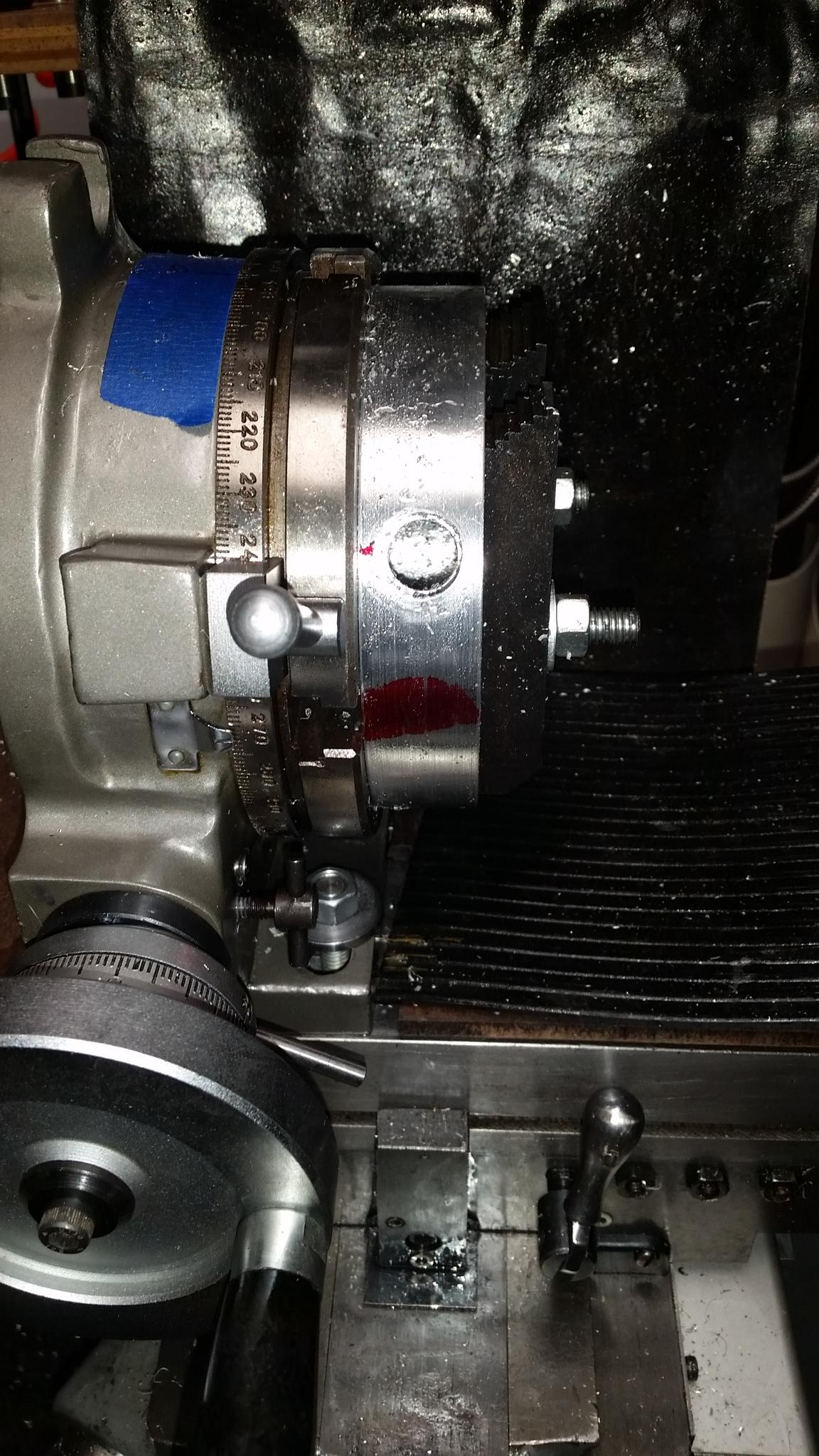

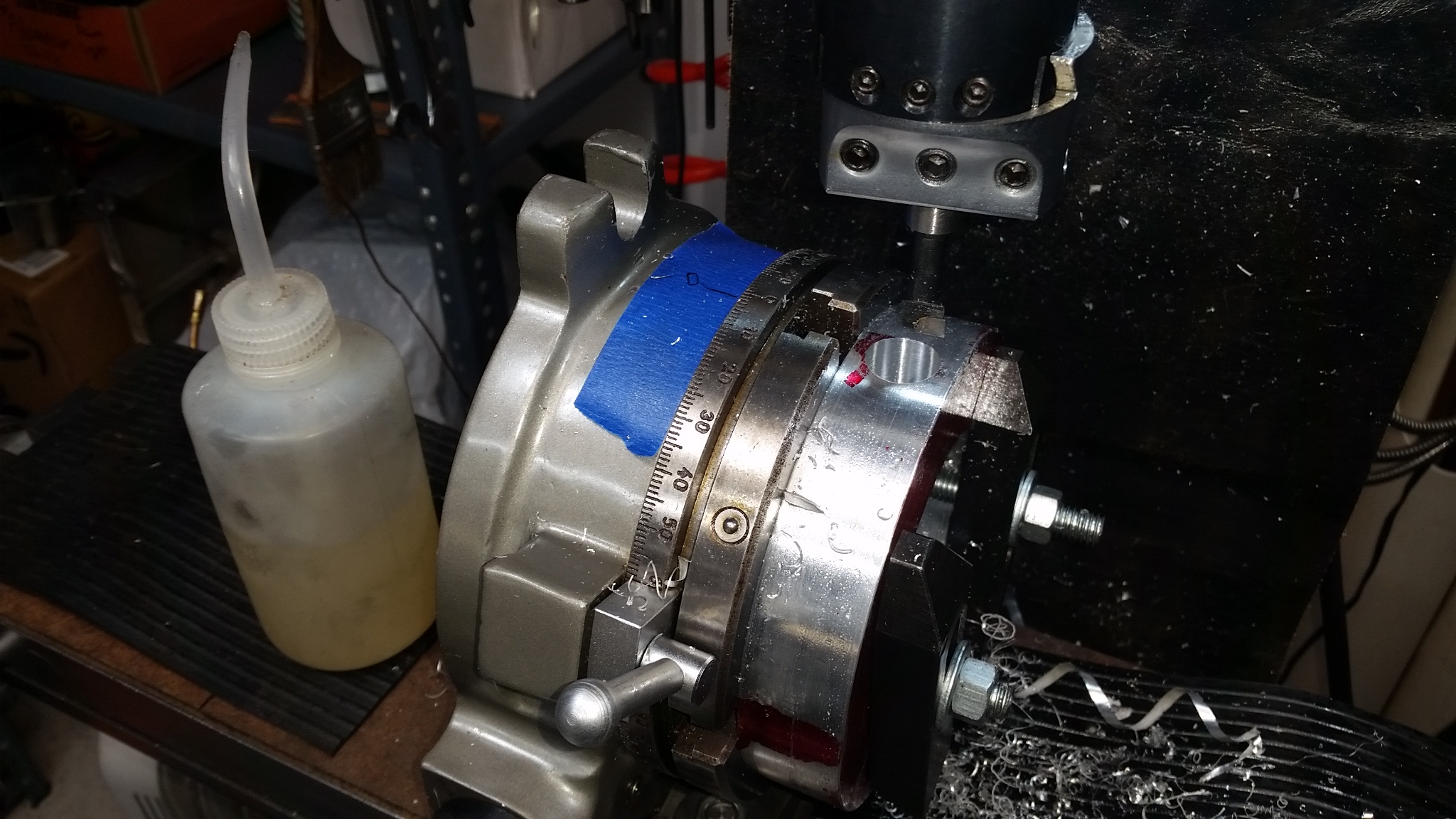

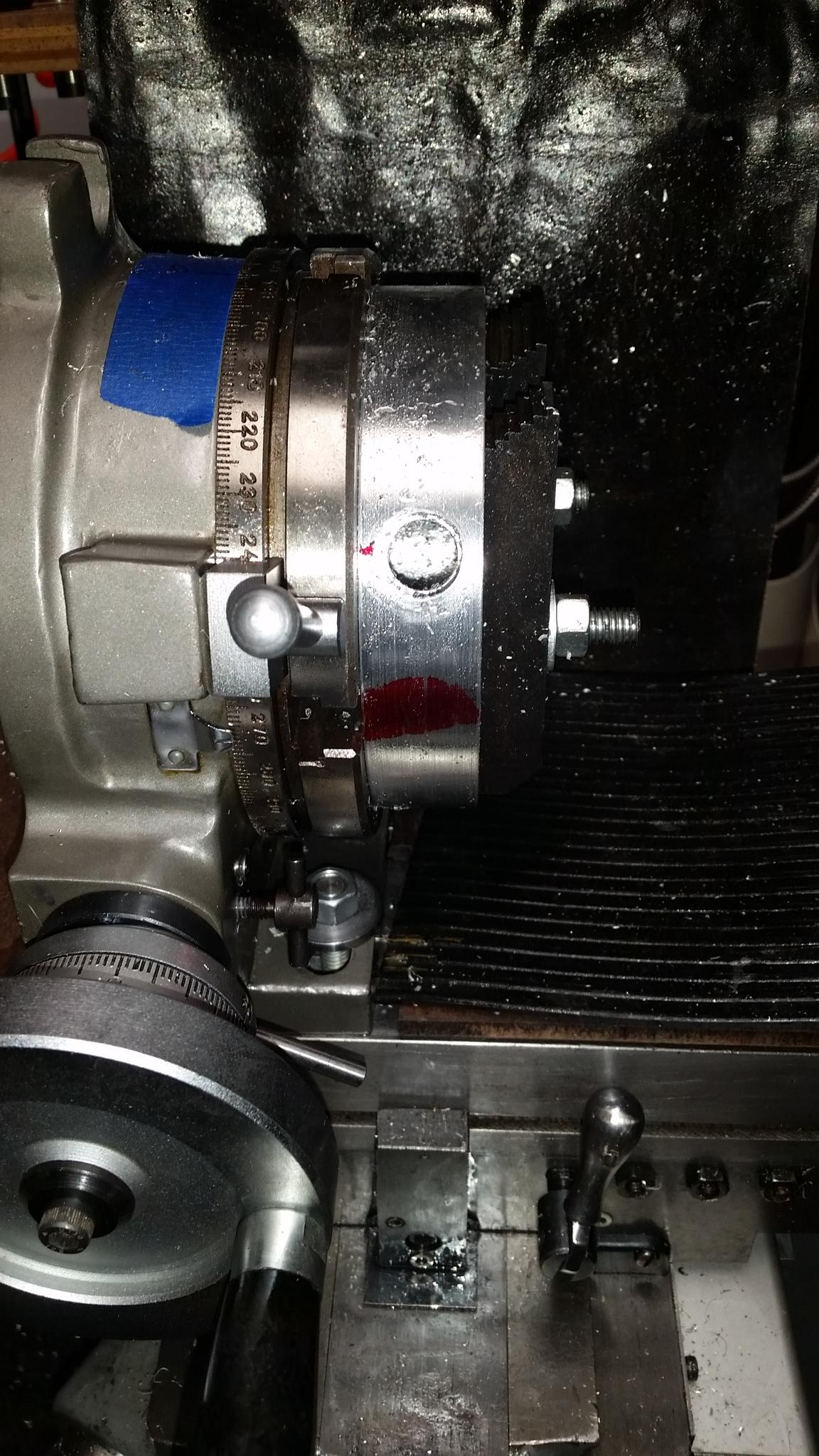

6061 for the ring .. I will be removing another 1/2 ... 1/4 from each side internally. I think the extra space will be helpful

Mild Steel for the finger material. I know.. mild against mild, but it's not going to be moving much. The left hand screw will also be mild steel. The caps .. don't know yet, will see what I have vs what fits.

6061 for the ring .. I will be removing another 1/2 ... 1/4 from each side internally. I think the extra space will be helpful

Mild Steel for the finger material. I know.. mild against mild, but it's not going to be moving much. The left hand screw will also be mild steel. The caps .. don't know yet, will see what I have vs what fits.

- Joined

- Nov 25, 2015

- Messages

- 8,284

Actually it doesn't seem very hard. I am more leery about making new wheel centers for my Delta Surface grinder. I have to hit those angles perfectly. As you know on your balancing shaft. But the hubs are internal and have me procrastinating. I don't need them that bad.Looks like you are on your way. Looks great so far.Not an easy project, imho.

This is a small project.. Look at those model engines those guys are building... Those are hard projects. Small in scale (that's hard), more critical in size, way more parts. Mine is just so I can hold longer parts that seem to hit me more frequently and with the small bore on the spindle often requires me to spin wheels figuring out what to do. My half dead center and small center get a work out often.. but how to center drill becomes a big issue...

ok I wrote a book for a simple thing.. Thank you.

- Joined

- Nov 25, 2015

- Messages

- 8,284

How are the pictures working out?

- Joined

- Mar 21, 2018

- Messages

- 1,597

How are the pictures working out?

Your pictures are very nice - good and large. Much better than your very first picture using Imgur.

- Joined

- Nov 25, 2015

- Messages

- 8,284

they are all imgur, the first one is a link to the imgur stream.Your pictures are very nice - good and large. Much better than your very first picture using Imgur.

- Joined

- Nov 25, 2015

- Messages

- 8,284

Gotta fix the knurling. It's not even. Don't know whether to remove, or add. Yes there's a screw up. I thought I was engaging the carriage, and instead the cross slide fed in. I wanted to cleanup the knurl to the end. DOH. I'm not going to re-do it. It's not a show piece, it's a tool.

- Joined

- Nov 25, 2015

- Messages

- 8,284

I was going to work on one of my wood projects, but I keep hearing this project call my name... Jeff finish me... Better get stronger meds...

Bored the holes for the 3 fingers, need one more hole for the hole to lock this down on the bed. Going to put it in the ring, rather than the base. It will give more holding power.

Bored the holes for the 3 fingers, need one more hole for the hole to lock this down on the bed. Going to put it in the ring, rather than the base. It will give more holding power.