-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steam Locomotive explained video.

- Thread starter DAN_IN_MN

- Start date

- Joined

- Aug 7, 2013

- Messages

- 655

Terry

You're welcome. Glad you enjoyed it!

A couple things I learned.

They used steam jets to direct where the coal went in the boiler.

They had a scoop under the engine to pick up water on the run! I forget how many barrels of water a minute they used. Something like 6!

They were very high maintenance!

You're welcome. Glad you enjoyed it!

A couple things I learned.

They used steam jets to direct where the coal went in the boiler.

They had a scoop under the engine to pick up water on the run! I forget how many barrels of water a minute they used. Something like 6!

They were very high maintenance!

- Joined

- Jan 22, 2011

- Messages

- 8,031

Nice video, Dan. Makes a person appreciate what it takes to keep those monsters running reliably.

Thanks for posting it.

Thanks for posting it.

- Joined

- Jan 16, 2020

- Messages

- 8

The appliances on locomotives, especially the larger ones, were many.

As for waterscoops, I believe that the New York Central was the sole user of such equipment. They were known as "The Water Level Route" for their tendency to follow rivers just about everywhere they went. Being close to water made it easy to keep the track pans full, but winter provided its own set of problems. I've read stories of some of the calamities that occurred when the scoops would stick in the down position. Everything from blown out tender sides to derailments.

From what I understand seeing a train taking on water via the scoop was quite a sight to behold.

I think most of us are familiar with the phrase "jerk-water town". From what I've read, railroad men referred to taking water by means of the scoop as 'jerking water'. Thus a town or place that had a track pan became known as a 'jerk-water town'.

As for waterscoops, I believe that the New York Central was the sole user of such equipment. They were known as "The Water Level Route" for their tendency to follow rivers just about everywhere they went. Being close to water made it easy to keep the track pans full, but winter provided its own set of problems. I've read stories of some of the calamities that occurred when the scoops would stick in the down position. Everything from blown out tender sides to derailments.

From what I understand seeing a train taking on water via the scoop was quite a sight to behold.

I think most of us are familiar with the phrase "jerk-water town". From what I've read, railroad men referred to taking water by means of the scoop as 'jerking water'. Thus a town or place that had a track pan became known as a 'jerk-water town'.

- Joined

- Aug 7, 2013

- Messages

- 655

Nice video, Dan. Makes a person appreciate what it takes to keep those monsters running reliably.

Thanks for posting it.

You're welcome!

No wonder they were replaced with diesel electric.

- Joined

- Nov 13, 2012

- Messages

- 165

Thanks for posting Dan. Great vid.

The last few years I have been doing some studying of the old steam engineering textbooks from the turn of the 20th century - just for fun.

In all of these books, locomotive design is considered as a special case. Like the video points out, the height and width of a locomotive is constrained - to fit under bridges, through tunnels, etc. So boiler, fire box, engine, all of the controls and appliances have to be squeezed into a small package. Since the height and width is constrained, the engines became longer and longer as power requirements increased. The ability of a long engine to handle a curve was a real problem. Many of the last (and longest) engines had two "trucks" of drives with a high pressure swivel/offset under one of the trucks to allow the engine to negotiate a curve.

Locomotive design also had some other requirements that most other steam engines did not have to deal with:

1) The loco had to be able to deliver full rated torque at 0 RPM in both forward and reverse to start the train.

Compare: Marine engines had the luxury to be able to start under relatively low torque (the propeller develops torque as the RPM increases)

Large stationary engines (mill engines) only had to run in one direction - and were often able to start under reduced loads

2) The loco had to be able to deliver a range of torques under a wide range of speed (up hill vs down hill)

Compare: Marine engines had a predicable torque vs speed curve and mill engines ran at constant speed and nearly constant load

3) Loco operators (engineer and fireman) had little access to the machinery while in operation.

Compare: marine engines and mill engines could be readily inspected, adjusted, and lubricated while in operation.

4) Nearly all locos ran with atmospheric exhaust - to save the weight and space of a condenser - thus the reason for huge consumption of water

Compare: marine engines and mill engines nearly always used condensers which increased engine efficiency and greatly reduced water consumption

Weight: The huge amounts of steel and cast iron required for a loco boiler/engine combination was actually helpful in supplying the traction requirements. Diesel and electric locomotives today typically have large blocks of steel or concrete to achieve enough weight to get the needed traction (steel wheels on steel rail).

Smoke and dust: A couple of years ago, my wife and I spent 4 days at the Western Minnesota Steam Threshers Reunion (WMSTR) near Moorhead, MN (one of the larger of such events in the US). They have dozens of steam thresher engines, a couple of locomotives, a couple of steam driven saw mills, several large stationery engines, several steam shovels - everything running on coal. It was a real treat. But, after 4 days of threshing dust, coal smoke, coal dust, soot, and oil-laden steam exhaust, it was good to get back to our (much cleaner) world of today.

For machining interest: WMSTR also has a fairly large 1915 (or so) version of a line shaft driven machine shop. The shop has two planers, 3 or 4 lathes, I think a shaper, and several drill presses, grinders, etc. all running off a line shaft system which is driven by a large hit-n-miss gasoline engine (which runs loaded and never misses). For the 4 days of the show the shop runs all day, every day. It was fun to watch the machinists manipulating belts to start/stop/reverse and change the speed of the machines - and using vintage measuring equipment. I can only assume that they were making usable parts. I recommend a visit if you ever get the chance.

Terry S.

The last few years I have been doing some studying of the old steam engineering textbooks from the turn of the 20th century - just for fun.

In all of these books, locomotive design is considered as a special case. Like the video points out, the height and width of a locomotive is constrained - to fit under bridges, through tunnels, etc. So boiler, fire box, engine, all of the controls and appliances have to be squeezed into a small package. Since the height and width is constrained, the engines became longer and longer as power requirements increased. The ability of a long engine to handle a curve was a real problem. Many of the last (and longest) engines had two "trucks" of drives with a high pressure swivel/offset under one of the trucks to allow the engine to negotiate a curve.

Locomotive design also had some other requirements that most other steam engines did not have to deal with:

1) The loco had to be able to deliver full rated torque at 0 RPM in both forward and reverse to start the train.

Compare: Marine engines had the luxury to be able to start under relatively low torque (the propeller develops torque as the RPM increases)

Large stationary engines (mill engines) only had to run in one direction - and were often able to start under reduced loads

2) The loco had to be able to deliver a range of torques under a wide range of speed (up hill vs down hill)

Compare: Marine engines had a predicable torque vs speed curve and mill engines ran at constant speed and nearly constant load

3) Loco operators (engineer and fireman) had little access to the machinery while in operation.

Compare: marine engines and mill engines could be readily inspected, adjusted, and lubricated while in operation.

4) Nearly all locos ran with atmospheric exhaust - to save the weight and space of a condenser - thus the reason for huge consumption of water

Compare: marine engines and mill engines nearly always used condensers which increased engine efficiency and greatly reduced water consumption

Weight: The huge amounts of steel and cast iron required for a loco boiler/engine combination was actually helpful in supplying the traction requirements. Diesel and electric locomotives today typically have large blocks of steel or concrete to achieve enough weight to get the needed traction (steel wheels on steel rail).

Smoke and dust: A couple of years ago, my wife and I spent 4 days at the Western Minnesota Steam Threshers Reunion (WMSTR) near Moorhead, MN (one of the larger of such events in the US). They have dozens of steam thresher engines, a couple of locomotives, a couple of steam driven saw mills, several large stationery engines, several steam shovels - everything running on coal. It was a real treat. But, after 4 days of threshing dust, coal smoke, coal dust, soot, and oil-laden steam exhaust, it was good to get back to our (much cleaner) world of today.

For machining interest: WMSTR also has a fairly large 1915 (or so) version of a line shaft driven machine shop. The shop has two planers, 3 or 4 lathes, I think a shaper, and several drill presses, grinders, etc. all running off a line shaft system which is driven by a large hit-n-miss gasoline engine (which runs loaded and never misses). For the 4 days of the show the shop runs all day, every day. It was fun to watch the machinists manipulating belts to start/stop/reverse and change the speed of the machines - and using vintage measuring equipment. I can only assume that they were making usable parts. I recommend a visit if you ever get the chance.

Terry S.

The appliances on locomotives, especially the larger ones, were many.

As for waterscoops, I believe that the New York Central was the sole user of such equipment. They were known as "The Water Level Route" for their tendency to follow rivers just about everywhere they went. Being close to water made it easy to keep the track pans full, but winter provided its own set of problems. I've read stories of some of the calamities that occurred when the scoops would stick in the down position. Everything from blown out tender sides to derailments.

From what I understan

d seeing a train taking on water via the scoop was quite a sight to behold.

I think most of us are familiar with the phrase "jerk-water town". From what I've read, railroad men referred to taking water by means of the scoop as 'jerking water'. Thus a town or place that had a track pan became known as a 'jerk-water town'.

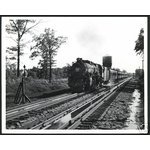

The PRR used this method quite bit as well, called it Taking water on the fly", express train, the K4 were almost always equipped, I was so impressed when younger I painted a scene from a photo.

Originally published in

Milepost, the Journal of

the Friends of the

Railroad Museum of

Pennsylvania.

April 1992.

Modified version in

Trains Magazine

May 1993

Scooping Water at the Ancora, NJ Track Pans; early 1950's

Scooping Water at the Ancora, NJ Track Pans; early 1950's