- Joined

- Dec 29, 2012

- Messages

- 394

I need to bend a 20mm stainless steel tube 180 degrees to 40mm radius so I must make a die for that.

I had a 10cm cast iron wheel that could be used as it is machined fairly easily using my mini lathe.

DESIGNING

The hardest thing was to design a stick that holds a cutting tool that would be fitted to the mini lathe and create the radius needed for the tube.

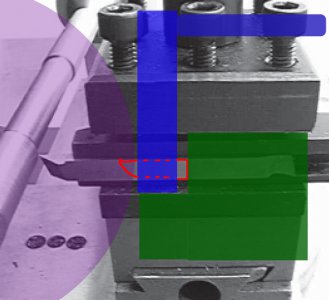

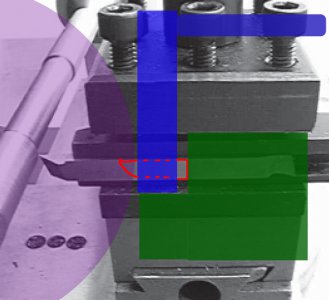

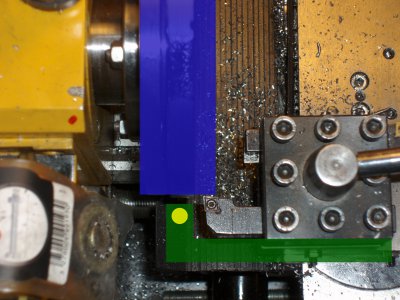

The idea to machine it directly does not apply as the material for the die (purple in the photo) is too large for my minilathe to be machined directly with a lathe tool. Moreover it is very hard (for me) to make a radius without some specialized tool.

Initial idea was to make a stick style rotating tool that holds an insert and will be supported at the side of the tool post (blue at the next sketch)

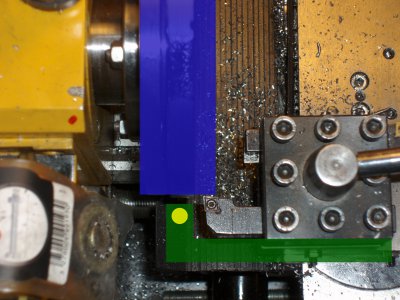

That was a poor idea that proved to be of no practical use as the tool, in order to be solidly and firmly supported by the tool post, could not be at a distance from it. When testing it the tool was too close to the toolpost to be used for the purpose.

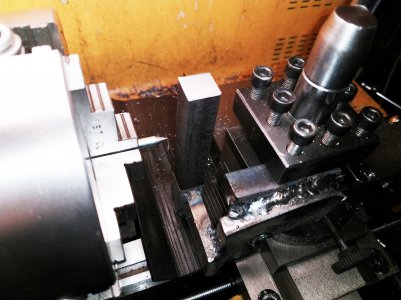

After some head scratching the best idea that came was to do as with my right cutter! Whenever I have something big the LH cutter cannot handle I use the RH cutter. Similarly I could support the tool at the back of the toolpost to make it solid and give it the proper distance to be of practical use for the purpose.

As the tool had to be strong some fairly thick (for a minilathe) steel had to be used

The cutter stick will be fit in the hole with the insert in the right height and it will be turned by hand. Some calculations ensured me that Th tool will be in the right distance to work the die.

CONSTRUCTION

I gathered the metal

Prepared the stick and the base

Welded the parts together

Testing on the toolpost

Marking insert height

Making a square hole 6mm

Rounding front side of the stick

Fitting a handle and the tool is ready

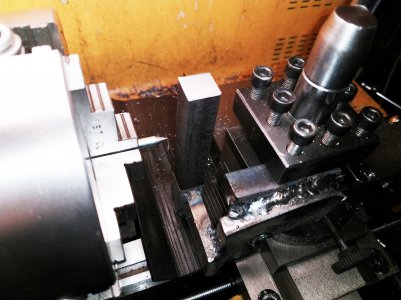

Using it on the minilathe

Results were great! It fits nicely the old tube so I can bend the new one.

Thanks for reading

Petros

I had a 10cm cast iron wheel that could be used as it is machined fairly easily using my mini lathe.

DESIGNING

The hardest thing was to design a stick that holds a cutting tool that would be fitted to the mini lathe and create the radius needed for the tube.

The idea to machine it directly does not apply as the material for the die (purple in the photo) is too large for my minilathe to be machined directly with a lathe tool. Moreover it is very hard (for me) to make a radius without some specialized tool.

Initial idea was to make a stick style rotating tool that holds an insert and will be supported at the side of the tool post (blue at the next sketch)

That was a poor idea that proved to be of no practical use as the tool, in order to be solidly and firmly supported by the tool post, could not be at a distance from it. When testing it the tool was too close to the toolpost to be used for the purpose.

After some head scratching the best idea that came was to do as with my right cutter! Whenever I have something big the LH cutter cannot handle I use the RH cutter. Similarly I could support the tool at the back of the toolpost to make it solid and give it the proper distance to be of practical use for the purpose.

As the tool had to be strong some fairly thick (for a minilathe) steel had to be used

The cutter stick will be fit in the hole with the insert in the right height and it will be turned by hand. Some calculations ensured me that Th tool will be in the right distance to work the die.

CONSTRUCTION

I gathered the metal

Prepared the stick and the base

Welded the parts together

Testing on the toolpost

Marking insert height

Making a square hole 6mm

Rounding front side of the stick

Fitting a handle and the tool is ready

Using it on the minilathe

Results were great! It fits nicely the old tube so I can bend the new one.

Thanks for reading

Petros

Last edited: