- Joined

- Nov 24, 2013

- Messages

- 254

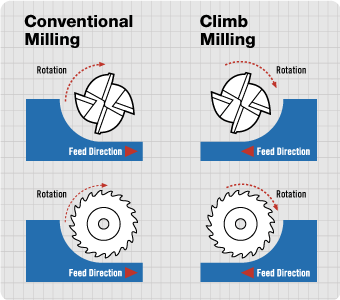

Are the rules for conventional or climb milling the same when you work on a LATH or a MILL?

If the answer is yes, then the posts below are not correct unless I misunderstand something which is quite possible due to lack of experience.

The first link below (posts #8 and 10) which refers to LATHE work says the push the stock against the cutter for conventional milling and the second link below (post #15) which refers to MILL work says to pull the stock against the cutter for conventional milling.

After reading many documents my understanding is for conventional milling, which I prefer, is to push the stock against the cutter (cutter turns clockwise) but now I wonder if this is true.

Nicolas

https://www.hobby-machinist.com/threads/are-any-rules-how-to-feed-lock-axes.69149/#post-579034

Posts #8 and 10 says “Note that by my method, you'll be cutting "conventional" while moving the part away from you and "climb" cutting while moving the part toward you. Pay attention to the way those cuts are acting and adjust your depth of cut accordingly. Climb cutting is more risky depending on machine stiffness, condition and the particular set up.

Climb cutting can pull the part into the cut, often because of backlash clearance in the lead screw, with undesirable results. Leaving a little drag (lock) on the travel might help. You just have to get to know your equipment and process”.

https://www.hobby-machinist.com/threads/confused-with-headstock-rpm-settings.72942/

Post #15 says “First pass was climb milling, second pass was conventional”

If the answer is yes, then the posts below are not correct unless I misunderstand something which is quite possible due to lack of experience.

The first link below (posts #8 and 10) which refers to LATHE work says the push the stock against the cutter for conventional milling and the second link below (post #15) which refers to MILL work says to pull the stock against the cutter for conventional milling.

After reading many documents my understanding is for conventional milling, which I prefer, is to push the stock against the cutter (cutter turns clockwise) but now I wonder if this is true.

Nicolas

https://www.hobby-machinist.com/threads/are-any-rules-how-to-feed-lock-axes.69149/#post-579034

Posts #8 and 10 says “Note that by my method, you'll be cutting "conventional" while moving the part away from you and "climb" cutting while moving the part toward you. Pay attention to the way those cuts are acting and adjust your depth of cut accordingly. Climb cutting is more risky depending on machine stiffness, condition and the particular set up.

Climb cutting can pull the part into the cut, often because of backlash clearance in the lead screw, with undesirable results. Leaving a little drag (lock) on the travel might help. You just have to get to know your equipment and process”.

https://www.hobby-machinist.com/threads/confused-with-headstock-rpm-settings.72942/

Post #15 says “First pass was climb milling, second pass was conventional”