- Joined

- Sep 22, 2010

- Messages

- 7,223

There are several things about setting up a VFD that I want to know:

1- Is there any benefit to running using single phase 220 and a VFD that converts single phase 220 to three phase 220

as opposed toa VFD that converts single phase 110 to three phase 220? What if anything is the difference?

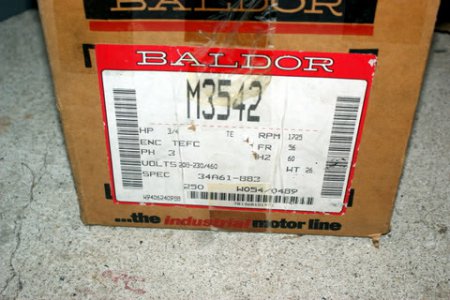

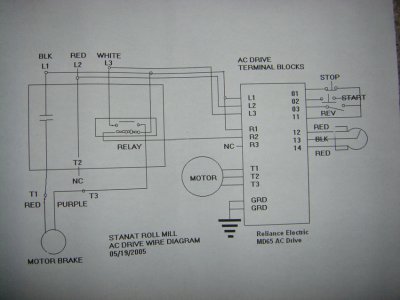

Next, I need to ID the components in this setup:

View attachment 33695

Looks like a fused disconnect (knife) switch connected to an outlet block and a corded grounded plug coming out of the disconnect.

I don't understand why use a corded plug if the disconnect is connected to a terminal block?

The cord coming out of the VFD is three phase twist plug and there is a female which connects to the male on the motor.

Why do it this way instead of a permanent hookup?

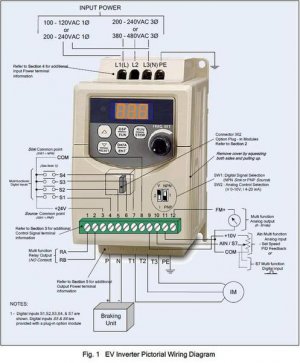

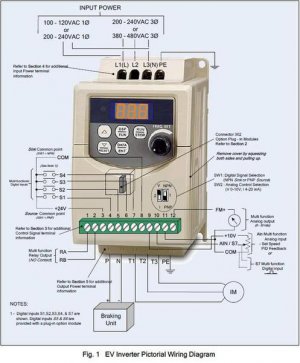

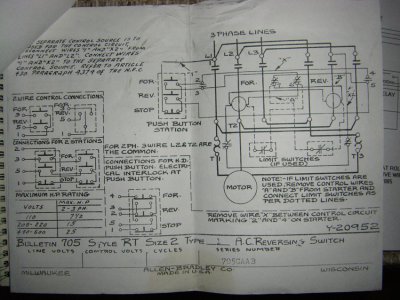

View attachment 33696

This shows the fused disconnect. Why is there a plug AND connection to a terminal block?

Where do you plug in to- not the terminal block. What is the purpose of the terminal block?

What type of connectors are those between the disconnect switch and terminal block (they look tapered).

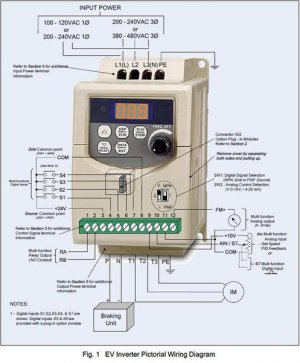

View attachment 33697

What are the wires that are taped with blue tape here?

Do these go to the drum switch?

Thanks for answering my stupid questions.

Can someone show the setup of the remote controls, including an Emergency Kill (off ) switch?

:tiphat:Nelson

1- Is there any benefit to running using single phase 220 and a VFD that converts single phase 220 to three phase 220

as opposed toa VFD that converts single phase 110 to three phase 220? What if anything is the difference?

Next, I need to ID the components in this setup:

View attachment 33695

Looks like a fused disconnect (knife) switch connected to an outlet block and a corded grounded plug coming out of the disconnect.

I don't understand why use a corded plug if the disconnect is connected to a terminal block?

The cord coming out of the VFD is three phase twist plug and there is a female which connects to the male on the motor.

Why do it this way instead of a permanent hookup?

View attachment 33696

This shows the fused disconnect. Why is there a plug AND connection to a terminal block?

Where do you plug in to- not the terminal block. What is the purpose of the terminal block?

What type of connectors are those between the disconnect switch and terminal block (they look tapered).

View attachment 33697

What are the wires that are taped with blue tape here?

Do these go to the drum switch?

Thanks for answering my stupid questions.

Can someone show the setup of the remote controls, including an Emergency Kill (off ) switch?

:tiphat:Nelson