- Joined

- Aug 22, 2012

- Messages

- 4,102

I would like to build a steam engine to drive a recumbent tricycle but cannot make up my mind of what design to follow.

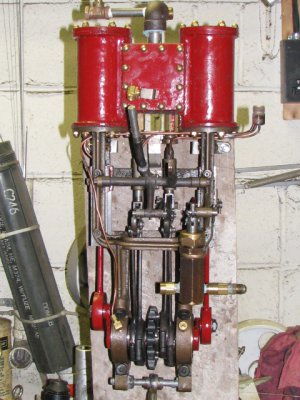

I'm leaning towards a twin cylinder double acting slide valve fired by propane and a flash boiler.

Anyone have any idea how large this engine should be to be able to drive this trike?

If I can get something that will drive the trike with possibly a bit of pedal assistance I will eventually turn it into a steampunk design for a bit of fun.

I'm leaning towards a twin cylinder double acting slide valve fired by propane and a flash boiler.

Anyone have any idea how large this engine should be to be able to drive this trike?

If I can get something that will drive the trike with possibly a bit of pedal assistance I will eventually turn it into a steampunk design for a bit of fun.