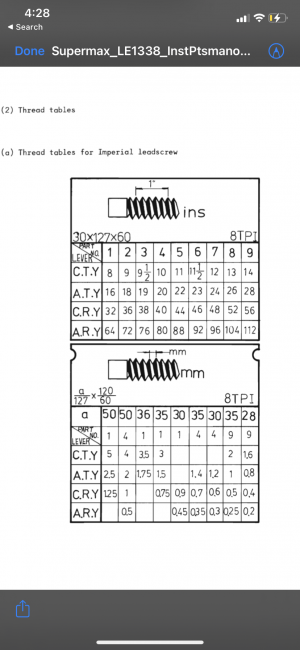

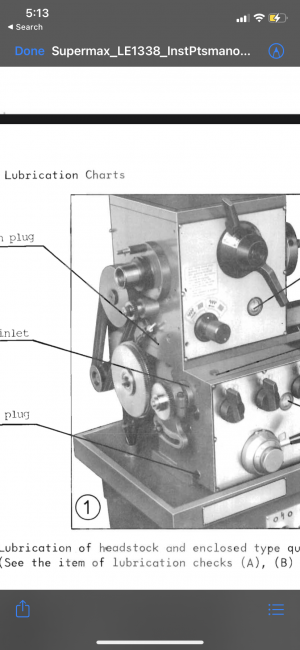

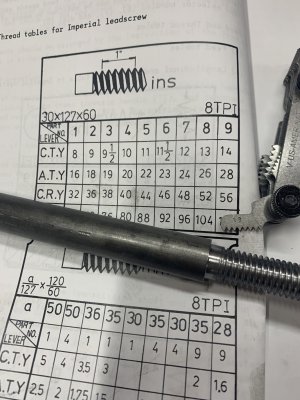

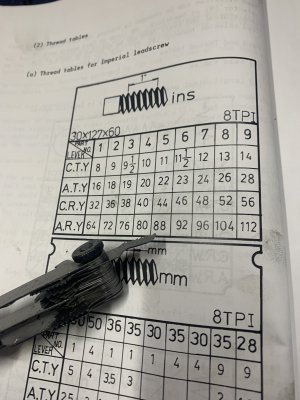

I have to state for the record that I have completely gone through the machine and have replaced basically everything. The lathe has little to no backlash now when threading. The lathe came with a 8 tpi lead screw. When cutting standard threads its100% dead nuts. My issue is with metric threading. I notice that when checking with a thread gauge the first couple threads line up but the remainder are off a couple thousands.... very very minimal. Still enough to make installing a nut impossible. What could be causing this ? The change gears are correct and like I said , standard threading is dead nuts ??

Attachments

-

EA10F881-F60D-40AF-9BCC-967A79B08D73.jpeg1.3 MB · Views: 125

EA10F881-F60D-40AF-9BCC-967A79B08D73.jpeg1.3 MB · Views: 125 -

82EDF88F-2770-46AA-BBEA-5EF19325A37C.jpeg1.1 MB · Views: 109

82EDF88F-2770-46AA-BBEA-5EF19325A37C.jpeg1.1 MB · Views: 109 -

B61B781A-3BC9-44EA-9997-7FF5CDE1509E.jpeg1.2 MB · Views: 106

B61B781A-3BC9-44EA-9997-7FF5CDE1509E.jpeg1.2 MB · Views: 106 -

7963C2DA-313E-4313-8EC1-3A9302096211.jpeg938.9 KB · Views: 100

7963C2DA-313E-4313-8EC1-3A9302096211.jpeg938.9 KB · Views: 100 -

0C59F451-FBD2-4BDF-84EB-FCB2345CCBCA.jpeg1.1 MB · Views: 109

0C59F451-FBD2-4BDF-84EB-FCB2345CCBCA.jpeg1.1 MB · Views: 109 -

0600361E-FE55-4E0D-B12A-DAEB73F91D7D.jpeg1.2 MB · Views: 129

0600361E-FE55-4E0D-B12A-DAEB73F91D7D.jpeg1.2 MB · Views: 129