-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Surface grinder double column

- Thread starter Traian

- Start date

Forgot to mentions I will not use big grinding wheel maximum 150mm but all different tipe in shape i want to be able to rebuild lathe saddle bed lathe.... i know grinding machine is long process and you cant take a deep cut.... thanks guy and sorry to asking to many questions

Hi Jim, I, been read a lot last night about steel and found like not really good for my build and general machine, I don’t know how f you had time to read other comments on post, according to this video is a cast iron machine and columns not looking really big, I don’t know never see it a planer what force is has in column compared with surface grinder?

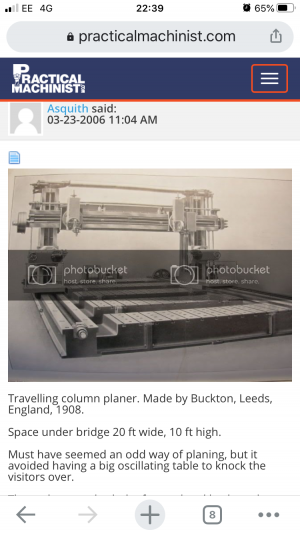

I found a big chunk cast iron table and a picture with old planer and gantry column movement!

Still will look for planer but here in UK is not really easy to found a double column and not really big, surface grinder most of them are bigger machine thanks

I found a big chunk cast iron table and a picture with old planer and gantry column movement!

Still will look for planer but here in UK is not really easy to found a double column and not really big, surface grinder most of them are bigger machine thanks

- Joined

- Jan 2, 2019

- Messages

- 6,519

Hi and welcome,

I would ask how many lathe beds are you planning on grinding? If it's just one or two then this may very well be a case where building a machine to build a machine isn't really a viable approach. I've been working on my small CNC mill/drill project for a while and still have several challenges to work through. I had a few pieces ground by my local machine shop on their Blanchard grinder that looked something like this one.

I'm not sure if this is the type of tool used for lathe bed reconditioning but it should give you and idea of the mass required for accurate large scale surface grinding.

The size and type of tool you are proposing would be a challenge for most professional shops, I suspect you could buy several new lathes for the cost of constructing an accurate tool in the size you're aiming for.

Me, I'm just a hack but these other guys really know their stuff so it will be good to listen.

Cheers,

John

I would ask how many lathe beds are you planning on grinding? If it's just one or two then this may very well be a case where building a machine to build a machine isn't really a viable approach. I've been working on my small CNC mill/drill project for a while and still have several challenges to work through. I had a few pieces ground by my local machine shop on their Blanchard grinder that looked something like this one.

I'm not sure if this is the type of tool used for lathe bed reconditioning but it should give you and idea of the mass required for accurate large scale surface grinding.

The size and type of tool you are proposing would be a challenge for most professional shops, I suspect you could buy several new lathes for the cost of constructing an accurate tool in the size you're aiming for.

Me, I'm just a hack but these other guys really know their stuff so it will be good to listen.

Cheers,

John

Thanks John for encouraging me!

I don’t want to do just one bed of lathe.

I understand everything everyone cheep telling me about weight of machine and all other things, this is a challenge for me in the end I reconsider my project doing with table movement on 2500x1200 surface base and i will do everything in grey cast iron,

I don’t want to do just one bed of lathe.

I understand everything everyone cheep telling me about weight of machine and all other things, this is a challenge for me in the end I reconsider my project doing with table movement on 2500x1200 surface base and i will do everything in grey cast iron,

- Joined

- Jan 2, 2019

- Messages

- 6,519

Thanks John for encouraging me!

I don’t want to do just one bed of lathe.

I understand everything everyone cheep telling me about weight of machine and all other things, this is a challenge for me in the end I reconsider my project doing with table movement on 2500x1200 surface base and i will do everything in grey cast iron,

Cast iron will probably be much better, if possible start with an existing machine as has been suggested. Not only will a good deal of the engineering already have been done, it will be much cheaper. Many times large old machines can be had for less than scrap value if you're able to move them.

John

Hi I know everyone here is right is better to found one already done, cheep looking for it but not much fond, all material will not gonna cost me a lot in cast iron and the base already i can say i have that, but bring each columns on a face from a solid will take me a lot of time to machine and after that grinding process.... I consider all that and know will cost,

If i will not found something like what I intended to build i will go for what intended, will be stress work but, nothing come easy in life if we want. Thanks

If i will not found something like what I intended to build i will go for what intended, will be stress work but, nothing come easy in life if we want. Thanks

I was thinking of this machine for long time, but I wasn’t right in the end and I thought will work if do gantry movement, I learn something from this, i keep looking for an old machine already built but i will be more pleased if I could do that by myself will make me happy id donee by my hand, easy to buy,

In my mind was a second choice for if i use v way sliding, as many I saw they are build in flat sliding/box sliding and i know usually v way sliding is much more precise but for my application don’t know if will be good this is the picture with I intended

In my mind was a second choice for if i use v way sliding, as many I saw they are build in flat sliding/box sliding and i know usually v way sliding is much more precise but for my application don’t know if will be good this is the picture with I intended