- Joined

- Feb 2, 2016

- Messages

- 50

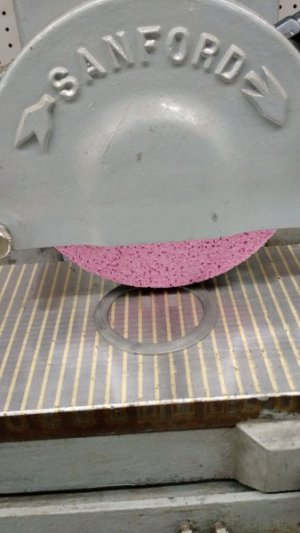

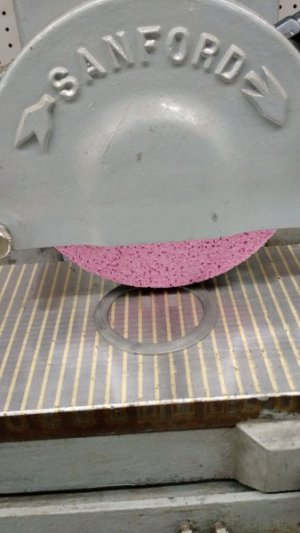

I have the need to grind a shim for a differential pinion. My grinder is an old Sanford 6x12 manual machine. The grinders vertical scale resolution is 0.001 so I don't quite think this is the best grinder to hold 0.0002" but I think with a little care and patience it will work. My questions is what wheel, and what should my y axis feed rate be. I currently have 2 wheels available. both are 7 x 1/2 J46 one is Ceramic gray and the other is Aluminum oxide open structure that I used to surface the mag chuck with. I am not adverse to purchasing a new wheel for this job. The shims are 82mm OD x 64mm ID x 1.9mm. I need to go down to 1.85mm ~ 0.073". I do have a mist cooling system available.