- Joined

- Jan 3, 2013

- Messages

- 190

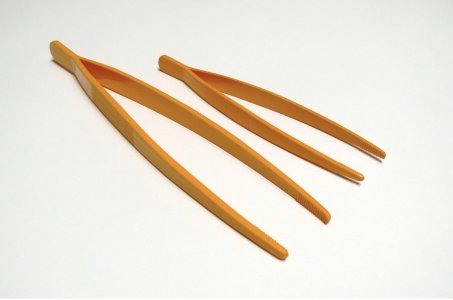

How about using a fish hook remover for grabbing stringy swarf on the lathe? I happened to run across one of these on sale for a few bucks and thought I would give it a try. Only tried it a few times so far, but it seems to work nicely - has a long narrow reach and a comfortable grip. Works better than the long reach pliers I was using before.