- Joined

- Nov 26, 2013

- Messages

- 11

Howdy, I'm building a variant of a Shortt-Synchronome clock, here's Sync parts that I've done so far,

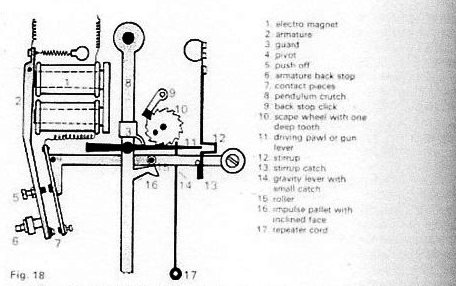

with the clockback on my Gorton 8d milling machine Its the first clock I've ever built. I've been using the Engineering in Miniature build series by Isaacs, along with the Hope-Jones DIY article, and feeding in some of the info from "Accurate Clock Pendulums" by Matthys, and using zuckerman "feels right" input too.

Its the first clock I've ever built. I've been using the Engineering in Miniature build series by Isaacs, along with the Hope-Jones DIY article, and feeding in some of the info from "Accurate Clock Pendulums" by Matthys, and using zuckerman "feels right" input too.

I hope to have a steel pendulum rod swinging under power sometime in February, if not the Invar36 one. The 16.5 lb bob is annealed 360 brass with the Matthys temp compensator scheme that I am modifying, instead of an Invar tube I want to use a quartz tube inside the bob, with an annealed 360 brass compensator exposed beneath the bob. I'm using my variation of the Shortt suspension trunnion for my clock, 3/4 dia. Invar bar on either side of the spring, Invar nuts on a Invar trunnion with sync style 1/8 pin . I've got both phosphor bronze and berillium copper shim stock for springs, along with a lot of phosphor bronze bar stock that I can cut down into one piece spring stock, for when I have my surface grinder running well...

I have an old mahogany box from a Pratt&Whitney super micrometer that I'm going to use for the case, its from WW2 and is old growth mahogany.

I have an old Sync slave clock, and when I have this clock working well in the house, am planning on buying a Microset with most of the bells and whistles so I can see how well ( or poorly) I built it, then I'll start drawing/machining the Shortt. For the Shortt, I've got a piece of Pyrex tube 1/2 wall x 6 ID x 60 for the tank, am scrounging for bell jars now...

Plan is to pour 6 tons of concrete sometime in '14 in the backyard..... 'cause my 100+ year old house just ain't stiff enough....I'll build a shed over the plinth, super insulate it, and see how the Sync runs when mounted on a stiff plinth and in a temperature controlled room, use the Microset for data acq, while the Shortt is being built.

Right now I'm gathering all the bits for building a heat treat oven. I have not been able to find a heat treat company who can anneal my Invar rods in what I consider the correct manner, or, they would charge me for heating an oven that will hold an F16 in it! so I'll build my own oven and do it myself. My electric oven will be 4.5x4.5x60 internal, vertical with a bottom drop door, nitrogen inert atmosphere...am also planning on cryogenic treating the Invar rods when the heat treatment is done, figure it can't hurt, may help..and from an engineering viewpoint I won't know either.. HA!

zuckerman story, ( true!) One of the salesmen I talked to at a HT company asked if I could cut my rods in two so he could lay them on his oven floor.

with the clockback on my Gorton 8d milling machine

Its the first clock I've ever built. I've been using the Engineering in Miniature build series by Isaacs, along with the Hope-Jones DIY article, and feeding in some of the info from "Accurate Clock Pendulums" by Matthys, and using zuckerman "feels right" input too.

Its the first clock I've ever built. I've been using the Engineering in Miniature build series by Isaacs, along with the Hope-Jones DIY article, and feeding in some of the info from "Accurate Clock Pendulums" by Matthys, and using zuckerman "feels right" input too. I hope to have a steel pendulum rod swinging under power sometime in February, if not the Invar36 one. The 16.5 lb bob is annealed 360 brass with the Matthys temp compensator scheme that I am modifying, instead of an Invar tube I want to use a quartz tube inside the bob, with an annealed 360 brass compensator exposed beneath the bob. I'm using my variation of the Shortt suspension trunnion for my clock, 3/4 dia. Invar bar on either side of the spring, Invar nuts on a Invar trunnion with sync style 1/8 pin . I've got both phosphor bronze and berillium copper shim stock for springs, along with a lot of phosphor bronze bar stock that I can cut down into one piece spring stock, for when I have my surface grinder running well...

I have an old mahogany box from a Pratt&Whitney super micrometer that I'm going to use for the case, its from WW2 and is old growth mahogany.

I have an old Sync slave clock, and when I have this clock working well in the house, am planning on buying a Microset with most of the bells and whistles so I can see how well ( or poorly) I built it, then I'll start drawing/machining the Shortt. For the Shortt, I've got a piece of Pyrex tube 1/2 wall x 6 ID x 60 for the tank, am scrounging for bell jars now...

Plan is to pour 6 tons of concrete sometime in '14 in the backyard..... 'cause my 100+ year old house just ain't stiff enough....I'll build a shed over the plinth, super insulate it, and see how the Sync runs when mounted on a stiff plinth and in a temperature controlled room, use the Microset for data acq, while the Shortt is being built.

Right now I'm gathering all the bits for building a heat treat oven. I have not been able to find a heat treat company who can anneal my Invar rods in what I consider the correct manner, or, they would charge me for heating an oven that will hold an F16 in it! so I'll build my own oven and do it myself. My electric oven will be 4.5x4.5x60 internal, vertical with a bottom drop door, nitrogen inert atmosphere...am also planning on cryogenic treating the Invar rods when the heat treatment is done, figure it can't hurt, may help..and from an engineering viewpoint I won't know either.. HA!

zuckerman story, ( true!) One of the salesmen I talked to at a HT company asked if I could cut my rods in two so he could lay them on his oven floor.