- Joined

- Jun 16, 2016

- Messages

- 221

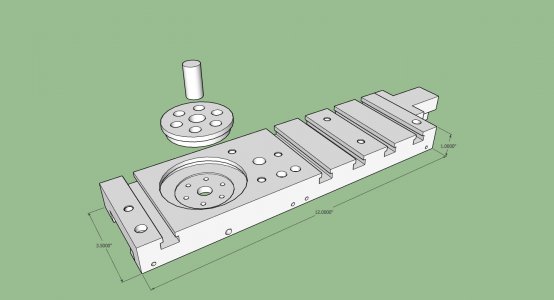

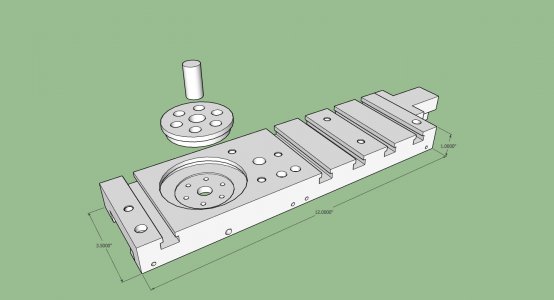

Just floating an idea here. I've gotten it into my head to try building an extended T-slot cross slide for my Model 200 based on Myford's design. To make building it "easier" I've made the circular compound T slot a two-piece design. I would also like to mount a magnetic encoder under the slide a la M-DRO (www.machine-dro.co.uk), which is the reason for the extension block on the tail end. I currently have a TouchDRO setup with the X-axis scale mounted in the space above the screw, it works really well, and the flat surface of the chip cover is very handy. It doesn't reduce the Z-axis travel, it doesn't interfere with the follower rest, and it minimizes sine error. While I was at it I added some ball oilers for the dovetails and the screw.

What would y'all think of a project series here and YouTube video(s)?

What would y'all think of a project series here and YouTube video(s)?