- Joined

- Nov 28, 2016

- Messages

- 2,344

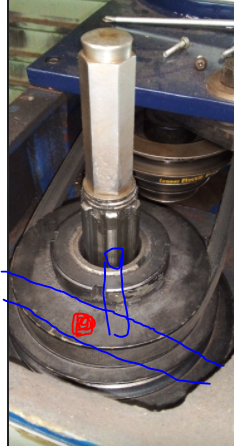

I'm guessing, based on what I see in your pictures, that your mill does not have a back gear... you should be fine mounting the magnet directly to the spindle pulley.

It should be a pretty easy install.

-Bear

It should be a pretty easy install.

-Bear