- Joined

- Sep 22, 2010

- Messages

- 7,223

Some Notes On Setting Up the Taig Milling Machine V2

Page 1, Here is page 2

I bought a new Taig CNC mill and took some more pictures as I was setting it up. You can see the previous setup page here.

If you are new to the world of machine tools, don't go overboard. Just get it setup and running and worry about adjustments as they arise, while learning about your machine as you use it.

The underside of the mill base.

The underside of the mill base.

Closeup of the y-axis gib retainer plate. The tall screw locks the gib (never used for CNC). The two side screws adjust the gib and the nuts lock the adjustment.

Closeup of the y-axis gib retainer plate. The tall screw locks the gib (never used for CNC). The two side screws adjust the gib and the nuts lock the adjustment.

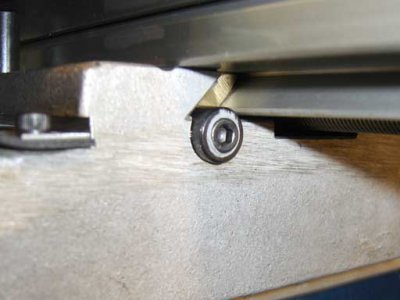

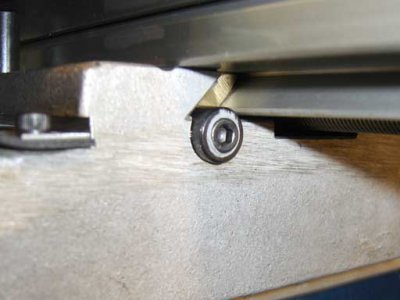

X axis gib screw.

X axis gib screw.

Underside of the y-axis bearing plate. Notice the small roll pin that locks the bearing unit in place on the plate.

Underside of the y-axis bearing plate. Notice the small roll pin that locks the bearing unit in place on the plate.

The base unit. Those screws in the table hold the small nuts used to hold the vise.

The base unit. Those screws in the table hold the small nuts used to hold the vise.

The column unit.

The column unit.

The circular boss that mates with the base unit. Clean the mating surface well before assembling.

The circular boss that mates with the base unit. Clean the mating surface well before assembling.

You can see the bottom z-axis gib screw here.

You can see the bottom z-axis gib screw here.

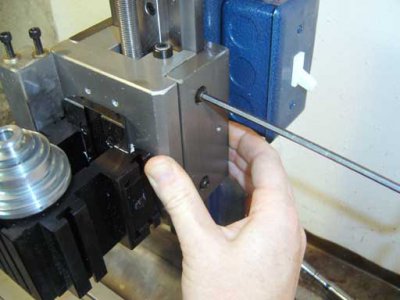

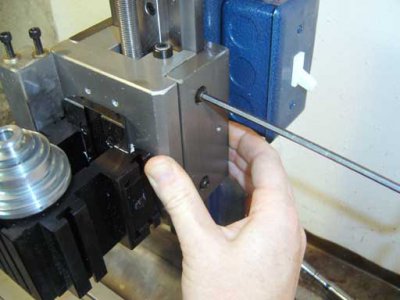

Holding the column up while tightening the nut to fasten the column to the base.

Holding the column up while tightening the nut to fasten the column to the base.

Notice that I have "choked up" on the wrench. You don't want to overtighten the nut.

Notice that I have "choked up" on the wrench. You don't want to overtighten the nut.

Squaring the column initially using a square against the headstock.

Squaring the column initially using a square against the headstock.

The top z-axis gib screw and part of the motor mount.

The two side screws hold the clamping shoes that retain the z-axis on the slide.

The z-axis top gib screw. These screws position the z-axis gib in the same manner as the x-axis tapered gib explained in the first mill setup article. The gib eliminates twist on the central z-axis slide bar.

The z-axis top gib screw. These screws position the z-axis gib in the same manner as the x-axis tapered gib explained in the first mill setup article. The gib eliminates twist on the central z-axis slide bar.

Adjusting the clamping shoe for the z-axis. The factor recommends that you squeeze it together with hand pressure then tighten the screws, without mounting the motor yet. This is usually fine from the factory so don't worry about it unless you need to. There used to be a screw from the front of the slide for adjustment but the factory found hand pressure was better for this adjustment.

Adjusting the clamping shoe for the z-axis. The factor recommends that you squeeze it together with hand pressure then tighten the screws, without mounting the motor yet. This is usually fine from the factory so don't worry about it unless you need to. There used to be a screw from the front of the slide for adjustment but the factory found hand pressure was better for this adjustment.

The y-axis gib.

The y-axis gib.

X-axis gib, wider end.

X-axis gib, wider end.

X-axis gib narrower end. Both of these screws should be tight once the position of the gib is adjusted.

X-axis gib narrower end. Both of these screws should be tight once the position of the gib is adjusted.

Go to Page 2 of this article

Back to cartertools.com

Some Notes On Setting Up the Taig Milling Machine V2

Page 2 - Back to Page 1

The CNC stepper motor mounts.

The CNC stepper motor mounts.

The tube threads onto the bearing block, and the collar clamps it once adjustement is completed.

The tube threads onto the bearing block, and the collar clamps it once adjustement is completed.

The mount completed.

The mount completed.

The stepper motor coupling half. The stepper shaft should be just at the bottom of the bore. The side screw clamps it tight.

The stepper motor coupling half. The stepper shaft should be just at the bottom of the bore. The side screw clamps it tight.

The coupling tubes inserted in the coupling half. One user found that trimming them to diminishing lengths made assembly easier. I asked the factory why tubing instead of solid rod and they said they found that solid rod would shear more easily under the stresses than tubing.

The coupling tubes inserted in the coupling half. One user found that trimming them to diminishing lengths made assembly easier. I asked the factory why tubing instead of solid rod and they said they found that solid rod would shear more easily under the stresses than tubing.

Inserting the tubes into the screw coupler half. This can take some wiggling and might drive you crazy. Turn the coupler half while rocking the motor around and you'll get it.

Inserting the tubes into the screw coupler half. This can take some wiggling and might drive you crazy. Turn the coupler half while rocking the motor around and you'll get it.

The gap is adjusted to be 1/8"-1/16" and the motor butts against the tube end.

The gap is adjusted to be 1/8"-1/16" and the motor butts against the tube end.

Another view.

Another view.

The motor is fastened to the plate. Make sure that the motor doesn't "cock" when the screws are tightened.

The motor is fastened to the plate. Make sure that the motor doesn't "cock" when the screws are tightened.

Basic assembly of the CNC mill completed.

Basic assembly of the CNC mill completed.

The motor mount attached to the headstock.

The motor mount attached to the headstock.

The motor mount plate attached with the two screws.

The motor mount plate attached with the two screws.

The motor, mounted.

The motor, mounted.

The pulleys should be aligned so that the motor and headstock shafts are parallel and the pulleys are in the same plane. The belt will suffer if care isn't taken with alignment. The motor can be adjusted up and down and for twist by moving the motor mount in the headstock slot. Be careful as it is heavy. if the belt makes a clicking noise then you need to adjust the alignment.

The pulleys should be aligned so that the motor and headstock shafts are parallel and the pulleys are in the same plane. The belt will suffer if care isn't taken with alignment. The motor can be adjusted up and down and for twist by moving the motor mount in the headstock slot. Be careful as it is heavy. if the belt makes a clicking noise then you need to adjust the alignment.

The motor assembled. When running the mill for the first few times you will notice that it has a hard time coming up to speed on the fastest pulley setting. After time the grease will thin and everything will start fine, but at first run it in the next to highest groove until the headstock warms up.

The motor assembled. When running the mill for the first few times you will notice that it has a hard time coming up to speed on the fastest pulley setting. After time the grease will thin and everything will start fine, but at first run it in the next to highest groove until the headstock warms up.

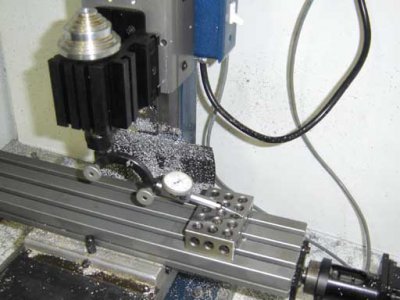

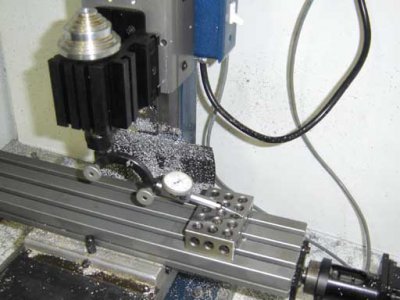

This is somewhat advanced, determining if the slide travel is perpendicular to the table by running the inidcator up and down a square (1-2-3 block) on the table, and adjusting the column by tapping with a soft hammer while the mounting nut is slightly loose.

This is somewhat advanced, determining if the slide travel is perpendicular to the table by running the inidcator up and down a square (1-2-3 block) on the table, and adjusting the column by tapping with a soft hammer while the mounting nut is slightly loose.

Once the z-axis slide is determined to run perpendicular to the table, you can check that the dovetail headstock mount in parallel to the travel of the slide by running the tip of an indicator along the dovetail. Slack all the dovetail mounting screws, but leave one slightly tight and adjust again by tapping with a soft hammer to bring into alignment. This can really make you crazy. But it will allow the greatest accuracy. But really, don't try this until you are comfortable adjusting things...

Once the z-axis slide is determined to run perpendicular to the table, you can check that the dovetail headstock mount in parallel to the travel of the slide by running the tip of an indicator along the dovetail. Slack all the dovetail mounting screws, but leave one slightly tight and adjust again by tapping with a soft hammer to bring into alignment. This can really make you crazy. But it will allow the greatest accuracy. But really, don't try this until you are comfortable adjusting things...

Closeup of the indicator tip against the dovetail. See below about Cosine error....

Closeup of the indicator tip against the dovetail. See below about Cosine error....

Once all that fiddling is done, test to see how well you have it aligned by sweeping the table.

Once all that fiddling is done, test to see how well you have it aligned by sweeping the table.

If you can get it to within .001 over 8"-12" you can call yourself an expert. I use the same block rather than two because I don't have a matched pair...

If you can get it to within .001 over 8"-12" you can call yourself an expert. I use the same block rather than two because I don't have a matched pair...

You want the tip of the indicator to be roughly parallel to the work surface to be gaged. You can read all about Cosine error here...if you don't have enough to think about already.

You want the tip of the indicator to be roughly parallel to the work surface to be gaged. You can read all about Cosine error here...if you don't have enough to think about already.

Back to Page 1

Back to cartertools.com

Page 1, Here is page 2

I bought a new Taig CNC mill and took some more pictures as I was setting it up. You can see the previous setup page here.

If you are new to the world of machine tools, don't go overboard. Just get it setup and running and worry about adjustments as they arise, while learning about your machine as you use it.

The underside of the mill base.

The underside of the mill base. Closeup of the y-axis gib retainer plate. The tall screw locks the gib (never used for CNC). The two side screws adjust the gib and the nuts lock the adjustment.

Closeup of the y-axis gib retainer plate. The tall screw locks the gib (never used for CNC). The two side screws adjust the gib and the nuts lock the adjustment. X axis gib screw.

X axis gib screw. Underside of the y-axis bearing plate. Notice the small roll pin that locks the bearing unit in place on the plate.

Underside of the y-axis bearing plate. Notice the small roll pin that locks the bearing unit in place on the plate. The base unit. Those screws in the table hold the small nuts used to hold the vise.

The base unit. Those screws in the table hold the small nuts used to hold the vise. The column unit.

The column unit. The circular boss that mates with the base unit. Clean the mating surface well before assembling.

The circular boss that mates with the base unit. Clean the mating surface well before assembling. You can see the bottom z-axis gib screw here.

You can see the bottom z-axis gib screw here. Holding the column up while tightening the nut to fasten the column to the base.

Holding the column up while tightening the nut to fasten the column to the base. Notice that I have "choked up" on the wrench. You don't want to overtighten the nut.

Notice that I have "choked up" on the wrench. You don't want to overtighten the nut. Squaring the column initially using a square against the headstock.

Squaring the column initially using a square against the headstock.

The top z-axis gib screw and part of the motor mount.

The two side screws hold the clamping shoes that retain the z-axis on the slide.

The z-axis top gib screw. These screws position the z-axis gib in the same manner as the x-axis tapered gib explained in the first mill setup article. The gib eliminates twist on the central z-axis slide bar.

The z-axis top gib screw. These screws position the z-axis gib in the same manner as the x-axis tapered gib explained in the first mill setup article. The gib eliminates twist on the central z-axis slide bar. Adjusting the clamping shoe for the z-axis. The factor recommends that you squeeze it together with hand pressure then tighten the screws, without mounting the motor yet. This is usually fine from the factory so don't worry about it unless you need to. There used to be a screw from the front of the slide for adjustment but the factory found hand pressure was better for this adjustment.

Adjusting the clamping shoe for the z-axis. The factor recommends that you squeeze it together with hand pressure then tighten the screws, without mounting the motor yet. This is usually fine from the factory so don't worry about it unless you need to. There used to be a screw from the front of the slide for adjustment but the factory found hand pressure was better for this adjustment. The y-axis gib.

The y-axis gib. X-axis gib, wider end.

X-axis gib, wider end. X-axis gib narrower end. Both of these screws should be tight once the position of the gib is adjusted.

X-axis gib narrower end. Both of these screws should be tight once the position of the gib is adjusted.Go to Page 2 of this article

Back to cartertools.com

Some Notes On Setting Up the Taig Milling Machine V2

Page 2 - Back to Page 1

The CNC stepper motor mounts.

The CNC stepper motor mounts. The tube threads onto the bearing block, and the collar clamps it once adjustement is completed.

The tube threads onto the bearing block, and the collar clamps it once adjustement is completed. The mount completed.

The mount completed. The stepper motor coupling half. The stepper shaft should be just at the bottom of the bore. The side screw clamps it tight.

The stepper motor coupling half. The stepper shaft should be just at the bottom of the bore. The side screw clamps it tight. The coupling tubes inserted in the coupling half. One user found that trimming them to diminishing lengths made assembly easier. I asked the factory why tubing instead of solid rod and they said they found that solid rod would shear more easily under the stresses than tubing.

The coupling tubes inserted in the coupling half. One user found that trimming them to diminishing lengths made assembly easier. I asked the factory why tubing instead of solid rod and they said they found that solid rod would shear more easily under the stresses than tubing. Inserting the tubes into the screw coupler half. This can take some wiggling and might drive you crazy. Turn the coupler half while rocking the motor around and you'll get it.

Inserting the tubes into the screw coupler half. This can take some wiggling and might drive you crazy. Turn the coupler half while rocking the motor around and you'll get it. The gap is adjusted to be 1/8"-1/16" and the motor butts against the tube end.

The gap is adjusted to be 1/8"-1/16" and the motor butts against the tube end. Another view.

Another view. The motor is fastened to the plate. Make sure that the motor doesn't "cock" when the screws are tightened.

The motor is fastened to the plate. Make sure that the motor doesn't "cock" when the screws are tightened. Basic assembly of the CNC mill completed.

Basic assembly of the CNC mill completed. The motor mount attached to the headstock.

The motor mount attached to the headstock. The motor mount plate attached with the two screws.

The motor mount plate attached with the two screws. The motor, mounted.

The motor, mounted. The pulleys should be aligned so that the motor and headstock shafts are parallel and the pulleys are in the same plane. The belt will suffer if care isn't taken with alignment. The motor can be adjusted up and down and for twist by moving the motor mount in the headstock slot. Be careful as it is heavy. if the belt makes a clicking noise then you need to adjust the alignment.

The pulleys should be aligned so that the motor and headstock shafts are parallel and the pulleys are in the same plane. The belt will suffer if care isn't taken with alignment. The motor can be adjusted up and down and for twist by moving the motor mount in the headstock slot. Be careful as it is heavy. if the belt makes a clicking noise then you need to adjust the alignment. The motor assembled. When running the mill for the first few times you will notice that it has a hard time coming up to speed on the fastest pulley setting. After time the grease will thin and everything will start fine, but at first run it in the next to highest groove until the headstock warms up.

The motor assembled. When running the mill for the first few times you will notice that it has a hard time coming up to speed on the fastest pulley setting. After time the grease will thin and everything will start fine, but at first run it in the next to highest groove until the headstock warms up. This is somewhat advanced, determining if the slide travel is perpendicular to the table by running the inidcator up and down a square (1-2-3 block) on the table, and adjusting the column by tapping with a soft hammer while the mounting nut is slightly loose.

This is somewhat advanced, determining if the slide travel is perpendicular to the table by running the inidcator up and down a square (1-2-3 block) on the table, and adjusting the column by tapping with a soft hammer while the mounting nut is slightly loose. Once the z-axis slide is determined to run perpendicular to the table, you can check that the dovetail headstock mount in parallel to the travel of the slide by running the tip of an indicator along the dovetail. Slack all the dovetail mounting screws, but leave one slightly tight and adjust again by tapping with a soft hammer to bring into alignment. This can really make you crazy. But it will allow the greatest accuracy. But really, don't try this until you are comfortable adjusting things...

Once the z-axis slide is determined to run perpendicular to the table, you can check that the dovetail headstock mount in parallel to the travel of the slide by running the tip of an indicator along the dovetail. Slack all the dovetail mounting screws, but leave one slightly tight and adjust again by tapping with a soft hammer to bring into alignment. This can really make you crazy. But it will allow the greatest accuracy. But really, don't try this until you are comfortable adjusting things... Closeup of the indicator tip against the dovetail. See below about Cosine error....

Closeup of the indicator tip against the dovetail. See below about Cosine error.... Once all that fiddling is done, test to see how well you have it aligned by sweeping the table.

Once all that fiddling is done, test to see how well you have it aligned by sweeping the table. If you can get it to within .001 over 8"-12" you can call yourself an expert. I use the same block rather than two because I don't have a matched pair...

If you can get it to within .001 over 8"-12" you can call yourself an expert. I use the same block rather than two because I don't have a matched pair... You want the tip of the indicator to be roughly parallel to the work surface to be gaged. You can read all about Cosine error here...if you don't have enough to think about already.

You want the tip of the indicator to be roughly parallel to the work surface to be gaged. You can read all about Cosine error here...if you don't have enough to think about already.Back to Page 1

Back to cartertools.com