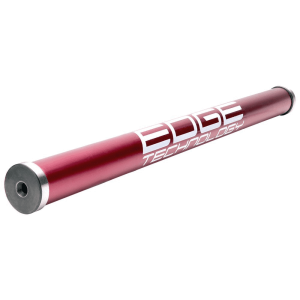

Guys just watch several Youtubes on how to do this which all seem very good.One way that I like which is little faster than other ways and don't have to use any stock to do so which I don't have.What I'm looking at is by Edge Tech. which looks to be an easy way and good for the beginner and can use it over and over again several yrs down the road.I was just wondering if anyone else has tried this and if you like it or not?Cost is 50.00 which I believe is a decent price,all have to do is take care of it.Any thoughts on this?