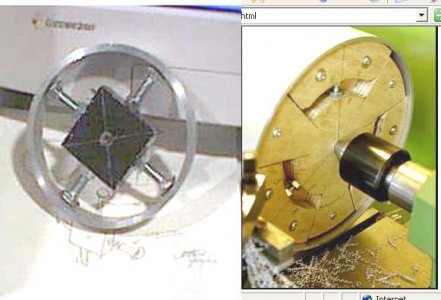

After seeing the nice step-by-step spider build by churchjw, thought I'd drop in a pic. of my tailstock spiders. The small one goes from 4" and up, the large one for 12" pipe. The 3/8" carriage bolts are easily set up with a 10mm end wrench. Both have double ball bearings for good support.

See Photo at link

See Photo at link

Last edited by a moderator: