- Joined

- Jan 10, 2019

- Messages

- 1,042

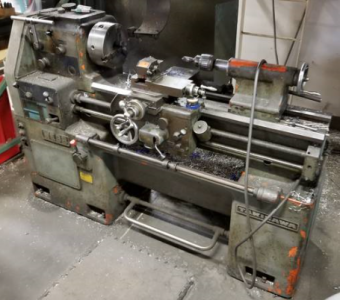

So I've been half-way watching for a lathe that could draw me away from rebuilding my old Grizzly lathe. One brand I consistently hear good things about is the TSL-800D variants, and a Webb turned up locally, asking price $3000 OBO. It's very dirty and the brake doesn't work (and may even be missing), but the gears and ways look great. The reason that I'm writing is about everything else, or lack there of.

It's got a KDK tool post and adjustable 10" Buck lathe, and that's it; no tool holders, no change gears (other than what's in it), no collet setup, no extra faceplate, no steady rest or follow rest. The seller has no way to get it on a trailer, and a local machine mover quoted $700 to move it 3 miles ("if I'm in the area, $1000 if not"). On top of that, the seller is amazingly unmotivated, making me wonder why people bother to put up an ad when they don't even talk to the perspective buyer.

Checking online, $3000 is about average but they often come with more stuff (I'm ignoring those annoying unicorn posts of people finding ones in perfect shape for $400). I've read enough here to know that obtaining change gears can be a big expense, never mind the lack of the other items. When I asked about the price, the guy said "oh I don't do that, you have to talk to this other guy, who just left for the day." I guess I'm pretty disappointed that they didn't even have the change gears that it came with (the shop is the original owner). Maybe they'd drop the price because of it, but I also know that these things are fairly rare (as in: hard to find, not necessarily valuable), so maybe this is normal and I'm being unreasonable.

One thing I do want to ask about is the consequences of a ASA A1-5" spindle (Webb) versus a D1-6 (Yuasa) spindle. Does it make any difference operationally? I know the bore in the D-spindle is slighter bigger, but how about chuck availability? He mentioned that they were unable to get new jaws for the Buck chuck, which I found surprising - I'd hate to guess what a new 10" adjustable Buck chuck goes for.

Part of me is excited to see a real serious lathe for sale, one that I can afford, but being excited means I man not be thinking clearly, and not knowing what I don't know, never mind being a bit overwhelmed by the thought of trying to get the 2500-3000 lb thing home. I guess I'm not sure why I'm posting, and I do feel better, and yes, I know, "first world problems."

It's got a KDK tool post and adjustable 10" Buck lathe, and that's it; no tool holders, no change gears (other than what's in it), no collet setup, no extra faceplate, no steady rest or follow rest. The seller has no way to get it on a trailer, and a local machine mover quoted $700 to move it 3 miles ("if I'm in the area, $1000 if not"). On top of that, the seller is amazingly unmotivated, making me wonder why people bother to put up an ad when they don't even talk to the perspective buyer.

Checking online, $3000 is about average but they often come with more stuff (I'm ignoring those annoying unicorn posts of people finding ones in perfect shape for $400). I've read enough here to know that obtaining change gears can be a big expense, never mind the lack of the other items. When I asked about the price, the guy said "oh I don't do that, you have to talk to this other guy, who just left for the day." I guess I'm pretty disappointed that they didn't even have the change gears that it came with (the shop is the original owner). Maybe they'd drop the price because of it, but I also know that these things are fairly rare (as in: hard to find, not necessarily valuable), so maybe this is normal and I'm being unreasonable.

One thing I do want to ask about is the consequences of a ASA A1-5" spindle (Webb) versus a D1-6 (Yuasa) spindle. Does it make any difference operationally? I know the bore in the D-spindle is slighter bigger, but how about chuck availability? He mentioned that they were unable to get new jaws for the Buck chuck, which I found surprising - I'd hate to guess what a new 10" adjustable Buck chuck goes for.

Part of me is excited to see a real serious lathe for sale, one that I can afford, but being excited means I man not be thinking clearly, and not knowing what I don't know, never mind being a bit overwhelmed by the thought of trying to get the 2500-3000 lb thing home. I guess I'm not sure why I'm posting, and I do feel better, and yes, I know, "first world problems."