-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Talk me out of a used Harbor Freight knee mill

- Thread starter MontanaLon

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,232

We hardly ever talk anyone out of buying a machine, unless it's a real rust pile casserole

- Joined

- Nov 23, 2014

- Messages

- 2,606

Hi Jeff,You have a picture of that 8X30? I'd like to see it if you don't mind.

Here's a photo of my Jet JVM-830. Grizzly makes a comparable one (along with others). I put a 4-axis TPAC Tools DRO on it and a X-axis power feed from a Grizzly round column Rong Fu mill/drill clone. Also put a smaller pulley on top of the motor cone pulley and the mid-shaft pulley to get the speed down to around 150 rpm. Been a pretty decent mill for a lot of years. Weighs around 900 lbs. and is pretty solid. Great size for a smaller shop. Oh, made a 5 1/2" riser block from a 8" round to get about 18" max distance from the spindle to the table.

Bruce

- Joined

- Mar 15, 2019

- Messages

- 708

For the record, you guys stink at following directions. I bought it. Had to disassemble to bring it home. Only sticky point was a machine clip in table I had to bend to remove.

Still had cosmoline full of aluminum chips only. Nota speck of steel.

Cleaning and reassembly will take a while. Then I can get the cosmoline off the mill and put it back together in basement.

Still had cosmoline full of aluminum chips only. Nota speck of steel.

Cleaning and reassembly will take a while. Then I can get the cosmoline off the mill and put it back together in basement.

- Joined

- Sep 28, 2013

- Messages

- 4,300

nice, I think you'll be pretty happy with it!

- Joined

- Oct 31, 2015

- Messages

- 23

Bruce

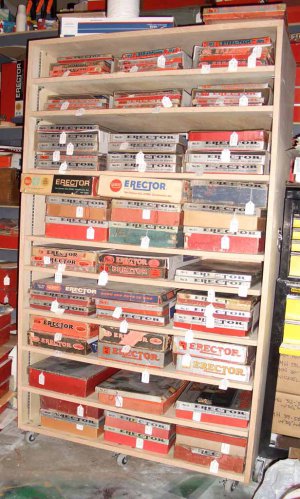

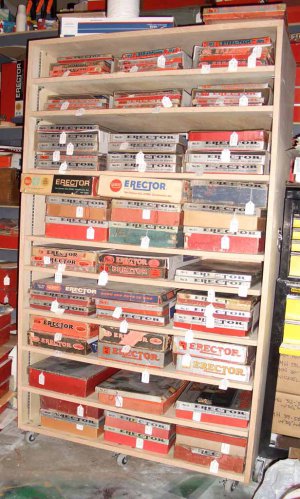

Love the Erector Set at the base of the mill. That just goes to prove you are still a 12 year old going on 13 for several decades. A great place to be BTW. I have a similar mill, a Jet JVM-840. Good little mills.

Best

Jim

View attachment 298454

Hi Jeff,

Here's a photo of my Jet JVM-830. Grizzly makes a comparable one (along with others). I put a 4-axis TPAC Tools DRO on it and a X-axis power feed from a Grizzly round column Rong Fu mill/drill clone. Also put a smaller pulley on top of the motor cone pulley and the mid-shaft pulley to get the speed down to around 150 rpm. Been a pretty decent mill for a lot of years. Weighs around 900 lbs. and is pretty solid. Great size for a smaller shop. Oh, made a 5 1/2" riser block from a 8" round to get about 18" max distance from the spindle to the table.

Bruce

Bruce

Love the Erector set at the base of the mill. That just goes to prove that you are still 11 years old going on 12 and holding after several decades. (A good place to be BTW). I have a similar Jet JVM-840 mill. Very good little machines.

Best

Jim_Z

View attachment 298454

- Joined

- Nov 23, 2014

- Messages

- 2,606

Hi Jim,

I find that the empty steel boxes make for good, sturdy storage. The box has 3/8" - 16 bolts, nuts, washers, T-nuts, clamps, etc. for the Jet mill. I used to have a pretty big collection of Gilbert stuff, something like 350 restored Erector sets. Now, nearly 20 years after I started picking up Gilbert chemistry sets, microscopes, magic sets, lead-casting sets, telescopes, puzzles, Erector sets and American Flyer trains, I can't put my finger on what started the "madness". Think I'm down to around 100 of them now. They did fund a lot of the improvements in my shop!

Bruce

I find that the empty steel boxes make for good, sturdy storage. The box has 3/8" - 16 bolts, nuts, washers, T-nuts, clamps, etc. for the Jet mill. I used to have a pretty big collection of Gilbert stuff, something like 350 restored Erector sets. Now, nearly 20 years after I started picking up Gilbert chemistry sets, microscopes, magic sets, lead-casting sets, telescopes, puzzles, Erector sets and American Flyer trains, I can't put my finger on what started the "madness". Think I'm down to around 100 of them now. They did fund a lot of the improvements in my shop!

Bruce

I ordered the HF 40939 Labor Day weekend and got it today. Is this machine relatively easy to break down ? I need to move it and don't have a pallet jack. It's still in the shipping crate. I'd also like to inspect and clean the castings. I figured on breaking it down to move would the best way to handle both tasks at the same time.

Tim

Tim

- Joined

- Mar 15, 2019

- Messages

- 708

It is pretty easy to remove the motor, both ends of the head, the swivel at the head and pretty much everything below that is various degrees of pain in the butt to pull apart. It isn't hard like replacing the spark plugs on a front wheel drive V-6 car but you can at least get a book that covers how to do it and how to get it back together.I ordered the HF 40939 Labor Day weekend and got it today. Is this machine relatively easy to break down ? I need to move it and don't have a pallet jack. It's still in the shipping crate. I'd also like to inspect and clean the castings. I figured on breaking it down to move would the best way to handle both tasks at the same time.

Tim

I had to break it down to be able to move it into the basement so the table and knee had to come off. The only part that I didn't have in pieces then was the spindle which I have broken down since then to clean and lubricate as it had the original rust preventative grease in it and was sticky.

Take lots of pictures as you take each piece off so you can get them back together more easily.

Breaking it down will certainly get you familiar with the machine and they really do need to be cleaned and lubed for best results.

I will warn you that the bondo they use on the castings is extremely brittle and you will get dings and scratches in it. I honestly think they would be better off to leave the painted parts as cast and make it less expensive. It is just cosmetic anyway.