- Joined

- Dec 31, 2010

- Messages

- 937

I have part of a rear mount taper attachment that I ultimately would like to put on my lathe. Not having any exposure to these tools there are a lot of questions. the first of which is "how wide to make the carriage that supports the free end of the taper attachment? Second is; there are no dovetails so should a bracket be made to keep the sliding parts from disengaging?

The attached picture shows the bottom side of the home made attachment behind the lathe. Two cap screws parallel to the cross side are how I intend to fasten the taper attachment to the carriage. There is a machined flat on the left side of the carriage but no bolts or hole. At this point in time I think if the parts are steel and in general 1/2 to 3/4 inch I won't have to drill a hole in the carriage.

Would appreciate comments from Clausing owners that have or used taper taper attachments.

Ray

The attached picture shows the bottom side of the home made attachment behind the lathe. Two cap screws parallel to the cross side are how I intend to fasten the taper attachment to the carriage. There is a machined flat on the left side of the carriage but no bolts or hole. At this point in time I think if the parts are steel and in general 1/2 to 3/4 inch I won't have to drill a hole in the carriage.

Would appreciate comments from Clausing owners that have or used taper taper attachments.

Ray

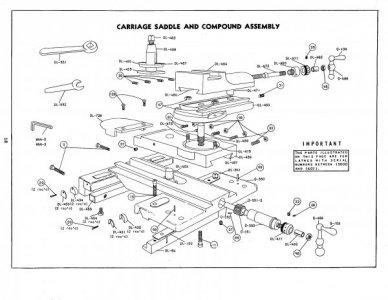

With one of those, the factory taper attachment included a replacement carriage, as they did not choose to build the cross-feed bar as a separate part as was done by both Atlas and Clausing. How many of the taper attachments were actually built and sold, I don't know. All that I do know is that they were in their catalogs, so they must have built at least a few. You might call Clausing and ask. You might at least be able to get either PDF's or TIF's of the drawings and parts manuals. I don't think that I have ever asked them for any of either for the early Clausing machines, but they do still have most of them for the equivalent Atlas machines.

With one of those, the factory taper attachment included a replacement carriage, as they did not choose to build the cross-feed bar as a separate part as was done by both Atlas and Clausing. How many of the taper attachments were actually built and sold, I don't know. All that I do know is that they were in their catalogs, so they must have built at least a few. You might call Clausing and ask. You might at least be able to get either PDF's or TIF's of the drawings and parts manuals. I don't think that I have ever asked them for any of either for the early Clausing machines, but they do still have most of them for the equivalent Atlas machines.