- Joined

- Jun 14, 2014

- Messages

- 410

Hello Vise Friends.

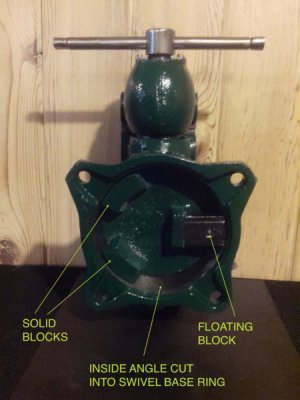

Recently I picked up a Taskmaster 4" vise. Some will call it a Wilton Bullet Clone or Knock-Off. It seems to be a well made vise. Its movement is smooth, it's pretty heavy for its size and it was well finished from the factory (many cheap import vises have uneven casting marks & sloppy grinder marks).

I can't find any information on it. Can anyone tell me:

1. Who manufactured it?

2. Country of origin? None stamped or cast anywhere on the vise.

3. Date of manufacture? I'm guessing 1970s?

4. Was it manufactured as a rebrand? If so, who distributed it?

Here is a picture:

Thanks in advance.

Recently I picked up a Taskmaster 4" vise. Some will call it a Wilton Bullet Clone or Knock-Off. It seems to be a well made vise. Its movement is smooth, it's pretty heavy for its size and it was well finished from the factory (many cheap import vises have uneven casting marks & sloppy grinder marks).

I can't find any information on it. Can anyone tell me:

1. Who manufactured it?

2. Country of origin? None stamped or cast anywhere on the vise.

3. Date of manufacture? I'm guessing 1970s?

4. Was it manufactured as a rebrand? If so, who distributed it?

Here is a picture:

Thanks in advance.