- Joined

- Feb 5, 2018

- Messages

- 637

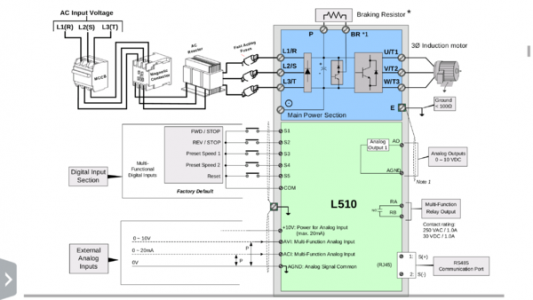

I just brought home a Gorton 1-22 mill and bought a TecoL510 VFD to power it. I have been reading about hooking these up quite a bit, and the more I read the more confused I become.

I tried to power it up by just hooking the output from the vfd to the 3 wires from the electrical box that contains all the relays and contactors. Nothing worked, so I just hooked th vfd directly to the leads from the motor. It fired right up. The issue I am facing is powering the feed motor on the table.

My question is, can I, or should I eliminate the contactors after the vfd and run directly to the motor?

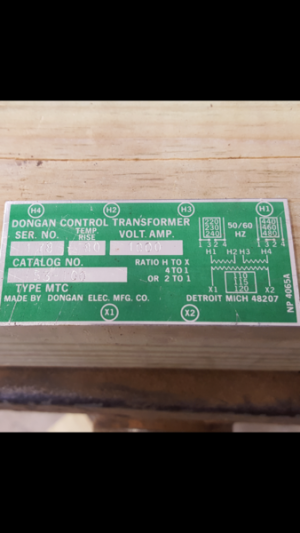

Question 2. How can I power the transformer for the power feed motor if I do eliminate the other stuff?

I will try to attach a picture of it.

Thanks for any help you can give me.

Joe Hynes

I tried to power it up by just hooking the output from the vfd to the 3 wires from the electrical box that contains all the relays and contactors. Nothing worked, so I just hooked th vfd directly to the leads from the motor. It fired right up. The issue I am facing is powering the feed motor on the table.

My question is, can I, or should I eliminate the contactors after the vfd and run directly to the motor?

Question 2. How can I power the transformer for the power feed motor if I do eliminate the other stuff?

I will try to attach a picture of it.

Thanks for any help you can give me.

Joe Hynes