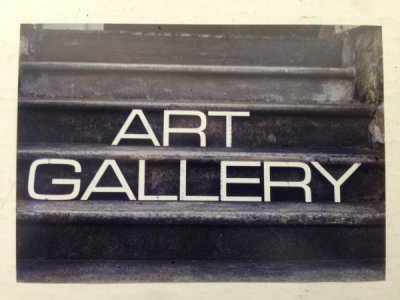

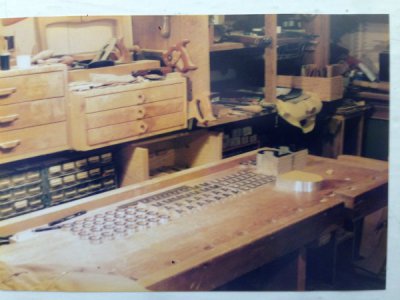

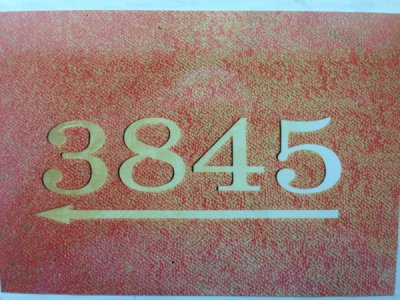

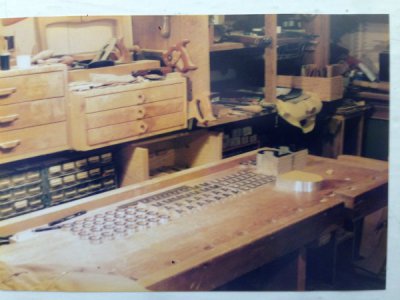

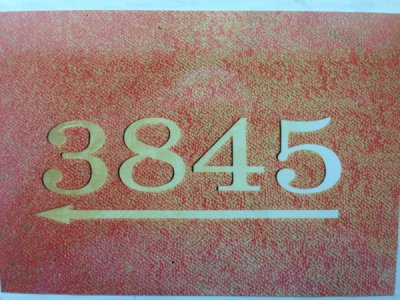

I'm not recommending that anyone go ahead and do this, especially if you're at all skittish around a bandsaw, but I have cut hundreds if not thousands of letters and numbers for architectural signs using only a slightly modified 14" vertical wood cutting bandsaw. And it wasn't even a good bandsaw, although I think it was one of the better knock-offs from the mid 1970's.

Aluminum was very popular, and I would cut anywhere from 1/8" thick to 1/2" thick. Brass (leaded) was also much used, although we would max out at 1/4" thick for that. Copper was the least fun, but fortunately there wasn't much call for it. Blades were dependant on the material as well as size of the job, and varied from 6 to 32 teeth per inch.

I did slow the blade down a bit, but not terribly much. I'm thinking maybe about 25 percent at the outside, only because that was the max I could go and still fit the pulleys inside the stock enclosure. I had a plexiglass platen on the table as well to cut down on blade clearance and allow smoother free-handing of the letters. No lubricant, not even blade wax. The most important thing in cutting tight internal shapes like serifs and such is to have a good exit strategy, kind of like runaway lanes on highways so you can get out if you need to.

Tip welding could be a problem, but not so much with a sharp blade. As the blades got dull through use there was more tendency to weld, so on a thick job (say 1/2" or 3/8" plate) it didn't pay to try to use anything but fresh blades. And on aluminum, nothing less than about sixteen teeth anyway or it would start to plug up. Chips embedding in the tires was more of a pain, and every now and again I would have to scrape them clean with a sharp block of wood. Letting them build up could lead to blade derailment, at least with my saw anyway. DoAll blades were the best, when we could get them.

I no longer have the old saw and also no longer do that type of work, but it was a pretty good sideline for nearly twenty years.

-frank