- Joined

- Jan 20, 2018

- Messages

- 5,620

While Carving My Own Tombstone (https://www.hobby-machinist.com/threads/carving-my-own-tombstone.81474/), I realized that the angle plate in question was big enough to be more than just an angle plate.

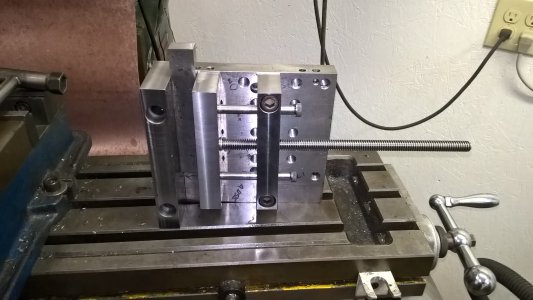

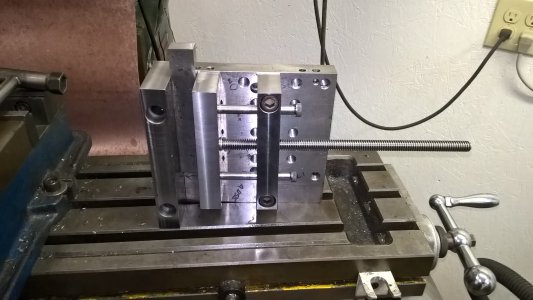

Here is the angle plate I started with. It was from an unknown piece of dedicated tooling and was ground as square as I could measure all over.

My original intent was to put a handle on it and drill and tap it 1/2-13 for tie down bolts. Then I added some tapped holes on the sides to mount side plates when needed.

It was at this point that I realized that this thing could be more, so much more. I took my inspiration from the Verti-Vise that Fred purchased when I was working for him.

I set about making a set of vise jaws from some 1 in. O-6 tool steel I had lying around. First the fixed jaw.

While working on the fixed jaw, I realized that this thing could serve another purpose (hint: note the large counterbores in the edge). The locations of mounting holes were constantly having to be adjusted to avoid the existing holes, bolts and dowels (which I assumed had been used, but couldn't see.)

Being designed on the fly, the moving jaw and its attachment took a couple of detours. My original intent was to use the 1/2-13 holes I had already put in the plate to mount the moving jaw. I had to rethink this after the holes for the guide pins proved to be in the way. This necessitated adding 8 more 1/2-13 holes to the angle plate. It's looking more swiss cheesy all the time.

This necessitated adding 8 more 1/2-13 holes to the angle plate. It's looking more swiss cheesy all the time.

So there we have it, the (soon to be) fabled and legendary Perverti-Vise (Regus Patoff). Maximum capacity is 5 in. (barely). I'm planning a few other details, including a series of holes in the fixed jaw for a dowel pin to serve as an adjustable stock support.

Oh wait, I almost forgot, I mentioned another purpose.

A two-piece table vise, capacity limited only by the length of the table.

That's all for now, I'll post updates as appropriate.

Here is the angle plate I started with. It was from an unknown piece of dedicated tooling and was ground as square as I could measure all over.

My original intent was to put a handle on it and drill and tap it 1/2-13 for tie down bolts. Then I added some tapped holes on the sides to mount side plates when needed.

It was at this point that I realized that this thing could be more, so much more. I took my inspiration from the Verti-Vise that Fred purchased when I was working for him.

I set about making a set of vise jaws from some 1 in. O-6 tool steel I had lying around. First the fixed jaw.

While working on the fixed jaw, I realized that this thing could serve another purpose (hint: note the large counterbores in the edge). The locations of mounting holes were constantly having to be adjusted to avoid the existing holes, bolts and dowels (which I assumed had been used, but couldn't see.)

Being designed on the fly, the moving jaw and its attachment took a couple of detours. My original intent was to use the 1/2-13 holes I had already put in the plate to mount the moving jaw. I had to rethink this after the holes for the guide pins proved to be in the way.

So there we have it, the (soon to be) fabled and legendary Perverti-Vise (Regus Patoff). Maximum capacity is 5 in. (barely). I'm planning a few other details, including a series of holes in the fixed jaw for a dowel pin to serve as an adjustable stock support.

Oh wait, I almost forgot, I mentioned another purpose.

A two-piece table vise, capacity limited only by the length of the table.

That's all for now, I'll post updates as appropriate.

Last edited: