- Joined

- Sep 29, 2017

- Messages

- 2,250

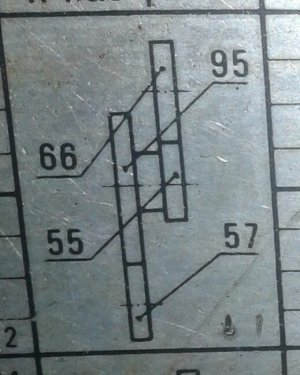

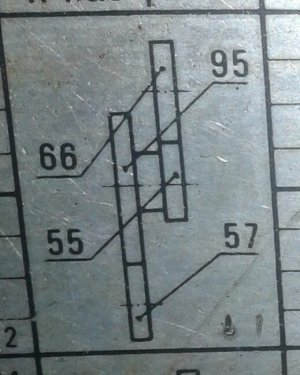

I have a question. If I want to make 4 new gears but I only have the number of teeth of each gear, how do I calculate the OD's of the gear blanks if I have none other variables available? Because I am making new gears,I don't have any other variables. The gears are for my lathe and in the picture below it shows the configuration.

If I have the OD,I can work out everything else,but I just can't figure out how to get the blank OD's. I know some are going to give me formulas using the module or DP or other variables ,but remember I do not have any of that. I hope someone can shine a very bright light on this,because I am starting to feel stupid not being able to figure this out.

Thanks guys

Michael

If I have the OD,I can work out everything else,but I just can't figure out how to get the blank OD's. I know some are going to give me formulas using the module or DP or other variables ,but remember I do not have any of that. I hope someone can shine a very bright light on this,because I am starting to feel stupid not being able to figure this out.

Thanks guys

Michael