- Joined

- Dec 16, 2014

- Messages

- 5

Time for a new project. I will be building a Die Filer. This will be a larger one than most of you are used to seeing. The Table will measure 14.000 X 14.000. It will be 16.000 tall. A "Scotch Yoke" will be utilized to convert the circular motion to linear motion of the file. The Table will also tilt forward 45 degrees.

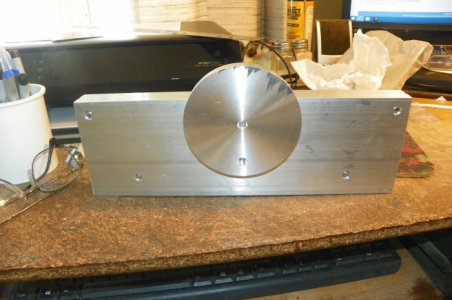

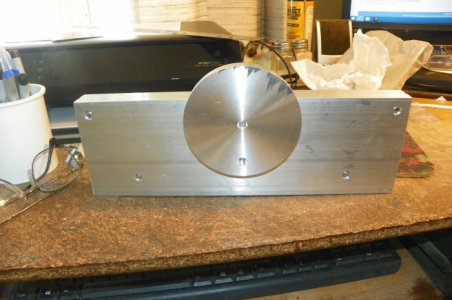

Here are a couple of pix of the Table Trunnions ready to be cut. They must be the same so they are bolted together. The 4 inch diameter piece bolted to that is to mount them off center by .625 inches in the rotary table.

I am getting together with bill50 to do the prints in CAD and PDF for all to download if they want.

"Billy G"

Here are a couple of pix of the Table Trunnions ready to be cut. They must be the same so they are bolted together. The 4 inch diameter piece bolted to that is to mount them off center by .625 inches in the rotary table.

I am getting together with bill50 to do the prints in CAD and PDF for all to download if they want.

"Billy G"