B

Bill Gruby

Forum Guest

Register Today

Bill;

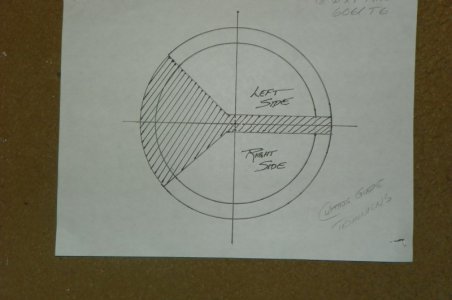

They were done for me by someone else. I was going to have Bill50 do them but this other person had already started them. They were done from my hand drawn prints importing them to a CAD program. These make my originals look amateur.

"Billy G"

They were done for me by someone else. I was going to have Bill50 do them but this other person had already started them. They were done from my hand drawn prints importing them to a CAD program. These make my originals look amateur.

"Billy G"