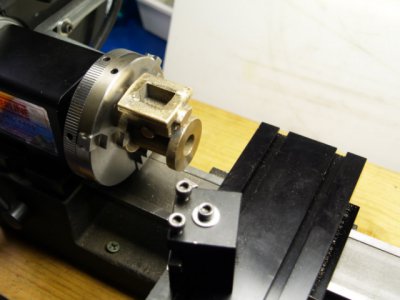

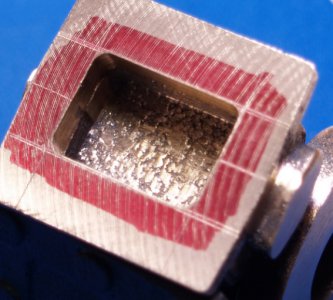

I've been bad at pictures, but I'm making some pretty good progress! I have the base done (except mounting holes and painting), and have finished everything on the crank shaft. The eccentric hub was fun!

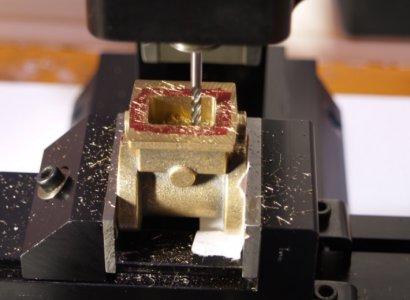

I've got a few more thing I want to do (mostly the crosshead and related mounting fixtures), but then I have to go after the cylinder. I have been putting that one off for quite a while now, but I think I'll have to go after it soon!

I realized today that I don't have any die holders that work with my round dies, so the two parts that require that either need to wait (or get a 40 tpi single point thread!), but I otherwise am getting stuff done at a pretty quick pace!