- Joined

- Nov 23, 2017

- Messages

- 1,191

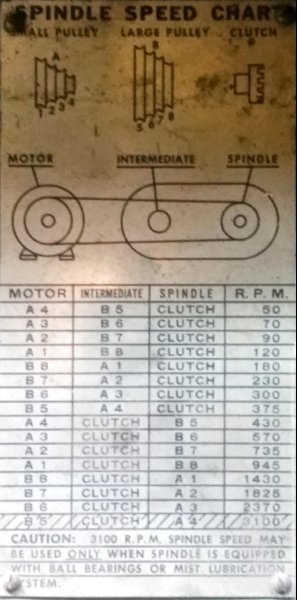

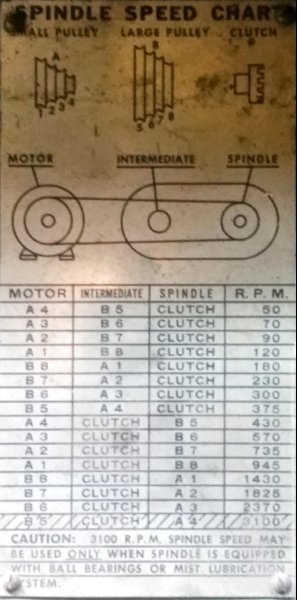

I bought this machine on eBay in Ohio early 2017 for $350. It has the biggest 2HP 3PH motor I have ever seen, the motor runs great but I can't get it to run slower than 1400 RPM, the pin spanner nuts on the spindle and the clutch won't turn. So I can't get the machine to run slowly enough to run high speed steel tooling.

Does anyone have any ideas for removing those pin spanner nuts?

Thank you

Does anyone have any ideas for removing those pin spanner nuts?

Thank you

Last edited: