There are lots of information sources including the web showing what clock and watch makers are doing these days. Please look up George Daniels on YouTube. He recently passed away, and was a master engineer, designer, machinist, mechanic. He made watches entirely alone, even the cases, and while you might not understand the functions of the watch, the result is breathtaking. There is a lot of mechanical watch and clock repairing being done, these days as well. There is a huge demand for high quality mechanical watches and the manufacturers are using the latest state of the art technologies, including computer aided design and manufacture, exotic metals (titanium, silicon, sapphire). Repairing old clocks and watches sometimes requires replacing worn or missing parts (like on that SB lathe, made in 1942) but much smaller. It can be tedious, of course, and sometimes a lot of figuring out what needs to be made. On more recent stuff, there is a fairly available supply of watch parts, as many watches have some interchangeable parts. Sometimes, though a small part may have to be made, as it is no longer available. Many of the small parts on a watch or clock must be made by hand, or with a watchmaker's lathe. Most shops don't have the very expensive, highly precise, machines required to make a relatively few parts during a year. Even cutting small gears requires a large investment in specialized tooling that can't be justified, so things like that are turned over to specialized makers with the skill and equipment to make something like a gear, pinion, or arbor, that may be less than 1/4" long. Fortunately, it does not have to be done too often. However, because of the value of some antique watches it is necessary to pay to have those things done. With clock repair, the parts are bigger, and the equipment is less expensive (and the parts are easier to see!). In my experience, (30 years) I think I have had to make less than 6 gears. It is not worth the expense of buying the machinery. There are those who love machinery, making clocks and their parts, so fortunately, getting parts made is not real difficult.

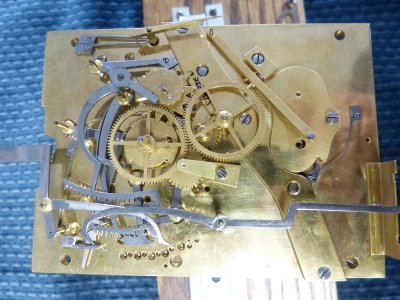

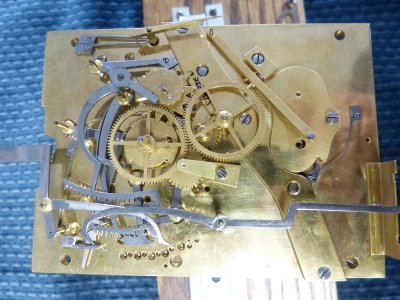

Attached is a picture of a fine carriage clock I restored some time ago. It is very large at about 9" with the handle up, and quite rare, because it plays Westminster chime on 4 coiled gongs.

I'll post some more pictures and links in the next few days.