- Joined

- Oct 17, 2018

- Messages

- 922

Thanks, everyone!

The Smithy BX-288 seller never returned my message. If it's an RF-40, then it's probably too big anyway. And, it sounds like it's not as easy to modify, buy parts for, etc...

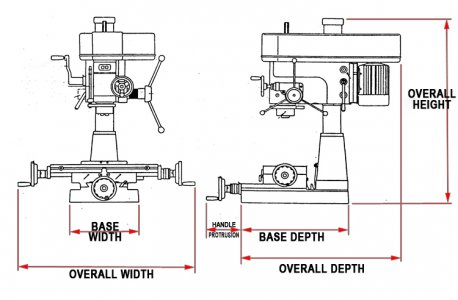

I need to go look at the RF-30 and see it in person. I looked at one a long time ago and I remember thinking it was huge, but I didn't take any measurements. 6. How much width do I need on either side for it? I have an area that's 66" wide and I'd like to know if it would fit there.

The biggest mill I could put in place of my LMS 3990 is either a PM-25 or a Grizzly G0704.

An RF-25 might fit as well. I'll have to keep my eyes out for one.

And, there's always just making what I have work. My vise only opens to 3", and I've had to modify a few designs to be smaller to fit. LMS sells a 5", but my machine is not listed as compatible, which makes me think it's too big. vise. I could also clamp the part directly to the table as well.

The Smithy BX-288 seller never returned my message. If it's an RF-40, then it's probably too big anyway. And, it sounds like it's not as easy to modify, buy parts for, etc...

I need to go look at the RF-30 and see it in person. I looked at one a long time ago and I remember thinking it was huge, but I didn't take any measurements. 6. How much width do I need on either side for it? I have an area that's 66" wide and I'd like to know if it would fit there.

The biggest mill I could put in place of my LMS 3990 is either a PM-25 or a Grizzly G0704.

An RF-25 might fit as well. I'll have to keep my eyes out for one.

And, there's always just making what I have work. My vise only opens to 3", and I've had to modify a few designs to be smaller to fit. LMS sells a 5", but my machine is not listed as compatible, which makes me think it's too big. vise. I could also clamp the part directly to the table as well.

Last edited: