-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thinking on buying a PM 1340GT

- Thread starter MattM

- Start date

I bought my 1340GT last summer. Huge step up from my Craftsman 12x36 in terms of stiffness. My guess is stiffness is less than the Colchester. The threading fast, along with the odd threading dial is kind of a pain- going to figure out how to thread upside down and away from the chuck to counter this to reduce the pucker factor and enjoy the higher speed finish. It is nice to dial in a number and hit it. The base has issues-I put a 3/8 plate and ribs inside the headstock end to get rid of the wobble created by the crown of the top plate. This could be eliminated by a difference build sequence, or build your own (see David Best thread). I went 3 phase and would do it again, original plan was to go VFD, but using RFC for now. Kind of wish I had gone to the 1440 GT for the additional weight and the enclosed gearbox but that depends on how obscene that stack of hundreds is. The no actual neutral kind of is a pain, but I'm getting over it. It is smooth, but should get better with use. The numbers on the gearbox not aligning with the pins is a thing, but I can count holes. I'm happy but not ecstatic, but it does make round things that you ask of it.

- Joined

- Sep 25, 2014

- Messages

- 1,103

Getting a 1340 as a companion to 10EE ? Certainly 2 lathes are better than one and a 13x40 gives a little more swing/gap/spindle hole/center distance and it maybe just that little bit more that makes all the difference. Do you have a hard space constraint? Even if you went with a 15 or 16 x 60 it doesn't take up much more space, is still not heavy & cumbersome and provides significant additional working room.

Doesn't everyone, all the time have "space constraints". Who is it among us who has too much shop space? Seriously though I can easily accommodate any lathe up to ten feet or so overall. And if I could just convince The Wife to park her new car outside I'd be phat.

The Monarch is lonely...

Now I'm looking at 1440's. Any input on that?

The Monarch is lonely...

Now I'm looking at 1440's. Any input on that?

- Joined

- Sep 25, 2014

- Messages

- 1,103

I 100% agree, the Monarch is probably lonely. I'm going to guess that taking good care of your wife's new car will go further than that "stack of C-notes" towards another lathe? What hard constraints do you have - power, stairs, a must do lathe job, . . . . Can you wait until another opportunity (like that Clausing/Colchester) shows up?

My small lathe is an 11x24 Smart & Brown - a very nice machine. My larger lathe is a 15x50 Colchester knock off (Enterprise) - also a nice enough machine. I find I use the Enterprise most of the time, even if the S&B would do the job just fine. The Enterprise is tooled a bit better, I like the foot switch/brake, the controls are a bit taller so I don't stoop and all the tooling is still light enough to handle (8" 3J, 10" 4J).

Obviously you will figure out your needs / wants. My #1 rationale for purchasing a machine is availability. If I think it is a good opportunity for me - I'll buy it. Whether it is somesort of a "perfect fit" is still a consideration, but since I'm buying at the bottom of the food chain the only choice I get is to take it or leave it. I've walked away from many opportunities, but I have also hauled some pretty nice pieces home. I bought the 15x60 about 35 years ago (first lathe). It took 3 years of looking until I found a nice "small" lathe (which is the 11x24 S&B) - that was 4 years ago. There are a few times I've wanted (needed?) a little bigger lathe - perhaps one day that suitable opportunity for a larger lathe will come my way? IMO a 16x60 would be a better companion for my shop and the 11x24 would get used more. In the mean time, several other machine opportunities have come my way - so I am quite happy playing with old (actually not even very old) iron. Hey, perhaps I can now step up to a 20x40ish? - I very rarely use the last couple feet of my existing lathe bed, but a larger spindle hole and bigger swing would be real nice.

It may be that if you went with a 13 or 14x40, you'd find that most of your jobs would still be done on only one of your lathes (the old 10EE or the new 13/14) since they are close in size - you would use the one which you were most comfortable with. If you opened up the spread there would be a technical reason in more cases to choose one over the other.

Let us know how you make out. David

My small lathe is an 11x24 Smart & Brown - a very nice machine. My larger lathe is a 15x50 Colchester knock off (Enterprise) - also a nice enough machine. I find I use the Enterprise most of the time, even if the S&B would do the job just fine. The Enterprise is tooled a bit better, I like the foot switch/brake, the controls are a bit taller so I don't stoop and all the tooling is still light enough to handle (8" 3J, 10" 4J).

Obviously you will figure out your needs / wants. My #1 rationale for purchasing a machine is availability. If I think it is a good opportunity for me - I'll buy it. Whether it is somesort of a "perfect fit" is still a consideration, but since I'm buying at the bottom of the food chain the only choice I get is to take it or leave it. I've walked away from many opportunities, but I have also hauled some pretty nice pieces home. I bought the 15x60 about 35 years ago (first lathe). It took 3 years of looking until I found a nice "small" lathe (which is the 11x24 S&B) - that was 4 years ago. There are a few times I've wanted (needed?) a little bigger lathe - perhaps one day that suitable opportunity for a larger lathe will come my way? IMO a 16x60 would be a better companion for my shop and the 11x24 would get used more. In the mean time, several other machine opportunities have come my way - so I am quite happy playing with old (actually not even very old) iron. Hey, perhaps I can now step up to a 20x40ish? - I very rarely use the last couple feet of my existing lathe bed, but a larger spindle hole and bigger swing would be real nice.

It may be that if you went with a 13 or 14x40, you'd find that most of your jobs would still be done on only one of your lathes (the old 10EE or the new 13/14) since they are close in size - you would use the one which you were most comfortable with. If you opened up the spread there would be a technical reason in more cases to choose one over the other.

Let us know how you make out. David

- Joined

- Dec 26, 2015

- Messages

- 2,079

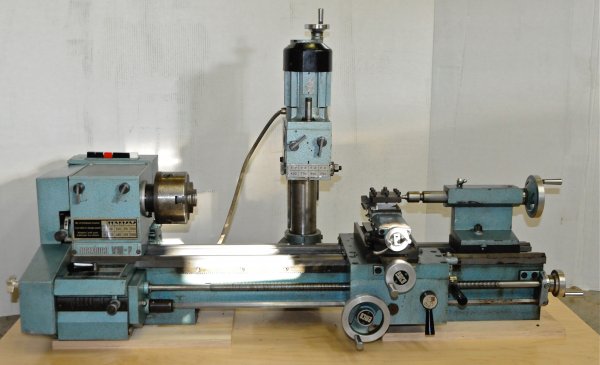

I have had a PM1340 for just over two years now. It replaced a very fine but old Swiss Emco V10-P.

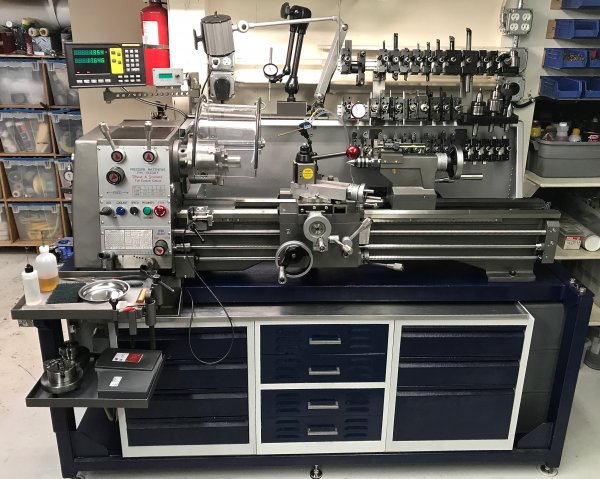

I approach these machines made in Asia with a totally different mindset from many or even most. I'm sure they function quite well out of the box, but I'm also sure there were a number of compromises made to contain cost that could be improved upon after acquiring the machine. So I approached getting the PM1340 with a view that it was going to be a project - a kit if you will - that would need enhancement for perform to my very high (excessive?) level of standards and also have esthetic qualities I could take pride in. Some people have said I turned a sows ear into a silk purse. Fine.

The basic machine a very solid. And I've been into every aspect and every component when I completely dismantled the lathe to strip it of the marginal paint job and put on a quality paint job that will stand up in an industrial environment and not chip of you drop your finglernail file on it. The guts of the machine are certainly well made and adequate for the size and horsepower of the machine. I found no issues with the headstock, the spindle, the lead- and threading screws, apron, cross-slide or tailstock. The spindle was slightly out of line, but quickly dialed in if you know what you're doing. The feed and threading gearbox is a Norton style with open bottom that needs oil and the oil drips out into the drip tray. If you don't mind that style gearbox, this one is solid, but the oil distribution method that comes with the machine is marginal IMO. I had a problem with the leadscrew binding and the clutch slipping which turned out to be a bushing lubrication problem and received parts in short order to replace the bushing. The dial distance rings on the compound and cross slide were clearly for a different model, but that was rectified with quick ship of new parts. Matt at Precision Matthews has been very supportive and responsive when I've asked.

Overall, I am very happy with my PM1340, but I have done extensive customization of it to bring it to higher levels of performance and ease of use. In addition to striping it down and repainting the machine, I upgraded all the fasteners to higher quality, provisioned it for easy toolless oil changing of the headstock. I replaced the factory motor with a Baldor vector motor, with new pulleys and belt, and installed all new electronic controls including a VFD, proximity stop, coolant control, an jog joystick. I installed a magnetic scale DRO on the cross slide and carriage, and provisioned it for Fogbuster MQL coolant. I completely threw out the oil system for the Norton gearbox and made my own multi-point drip one-shot system for that aspect. Designed an build a custom Mitutoyo DRO on the tailstock, replaced all the handles with custom knurled stainless handles, added a tachometer and a spider to the spindle. I replaced the rubber bed wipers with felt versions, and made my own Set-True ER40 collet chuck. I also made a solid tool post mount that can swap out with the compound to get much better rigidity. And I made my own Torsion-beam based stand. Mark Jacobs did the controls and I will be forever grateful for his effort.

The full build log is here: https://flic.kr/s/aHskYxDKzN

There is also a long earlier thread on this build here on H-M you can find here: https://www.hobby-machinist.com/threads/pm1340-the-best-jacobs-full-custom-edition.58507/

For my needs, this machine performs very well and I get very aggressive machining 316 stainless steel at times. I am really glad to have the VFD and the additional torque of the vector motor at slow speeds, and the proximity stop takes all the pucker factor out of threading up to a shoulder.

I approach these machines made in Asia with a totally different mindset from many or even most. I'm sure they function quite well out of the box, but I'm also sure there were a number of compromises made to contain cost that could be improved upon after acquiring the machine. So I approached getting the PM1340 with a view that it was going to be a project - a kit if you will - that would need enhancement for perform to my very high (excessive?) level of standards and also have esthetic qualities I could take pride in. Some people have said I turned a sows ear into a silk purse. Fine.

The basic machine a very solid. And I've been into every aspect and every component when I completely dismantled the lathe to strip it of the marginal paint job and put on a quality paint job that will stand up in an industrial environment and not chip of you drop your finglernail file on it. The guts of the machine are certainly well made and adequate for the size and horsepower of the machine. I found no issues with the headstock, the spindle, the lead- and threading screws, apron, cross-slide or tailstock. The spindle was slightly out of line, but quickly dialed in if you know what you're doing. The feed and threading gearbox is a Norton style with open bottom that needs oil and the oil drips out into the drip tray. If you don't mind that style gearbox, this one is solid, but the oil distribution method that comes with the machine is marginal IMO. I had a problem with the leadscrew binding and the clutch slipping which turned out to be a bushing lubrication problem and received parts in short order to replace the bushing. The dial distance rings on the compound and cross slide were clearly for a different model, but that was rectified with quick ship of new parts. Matt at Precision Matthews has been very supportive and responsive when I've asked.

Overall, I am very happy with my PM1340, but I have done extensive customization of it to bring it to higher levels of performance and ease of use. In addition to striping it down and repainting the machine, I upgraded all the fasteners to higher quality, provisioned it for easy toolless oil changing of the headstock. I replaced the factory motor with a Baldor vector motor, with new pulleys and belt, and installed all new electronic controls including a VFD, proximity stop, coolant control, an jog joystick. I installed a magnetic scale DRO on the cross slide and carriage, and provisioned it for Fogbuster MQL coolant. I completely threw out the oil system for the Norton gearbox and made my own multi-point drip one-shot system for that aspect. Designed an build a custom Mitutoyo DRO on the tailstock, replaced all the handles with custom knurled stainless handles, added a tachometer and a spider to the spindle. I replaced the rubber bed wipers with felt versions, and made my own Set-True ER40 collet chuck. I also made a solid tool post mount that can swap out with the compound to get much better rigidity. And I made my own Torsion-beam based stand. Mark Jacobs did the controls and I will be forever grateful for his effort.

The full build log is here: https://flic.kr/s/aHskYxDKzN

There is also a long earlier thread on this build here on H-M you can find here: https://www.hobby-machinist.com/threads/pm1340-the-best-jacobs-full-custom-edition.58507/

For my needs, this machine performs very well and I get very aggressive machining 316 stainless steel at times. I am really glad to have the VFD and the additional torque of the vector motor at slow speeds, and the proximity stop takes all the pucker factor out of threading up to a shoulder.

The reality is we all (most of us anyway) have money constraints. If money were no object, then space constraints wouldn't be an issue either.

Ha, no truer statement has ever been made!

- Joined

- Jan 7, 2016

- Messages

- 3,257

Matt M: I have a PM1022 lathe. Not in the same league as you but it is Chinese and "ok" at best. I also bought a PM833T mill and being made in Tiawan the fit and finish is noticeably better.

If I were you, I would look at the 1440. Matt from Precision Matthews has superb customer service, which is certainly worth something when dealing with machinery. My next lathe will either be the 1340GT or 1440GT.

Also, I recently discovered Eisen Machinery which has Tiwain made machines. I am trying to compare them and PM but it is laborious getting an accurate comparison. I have read good things about Eisen too. Of the 1440's I was trying to compare, it seemed that Eisen was a good deal cheaper, but cannot confirm that all specs are apples to apples. Not much help I know but...

If I were you, I would look at the 1440. Matt from Precision Matthews has superb customer service, which is certainly worth something when dealing with machinery. My next lathe will either be the 1340GT or 1440GT.

Also, I recently discovered Eisen Machinery which has Tiwain made machines. I am trying to compare them and PM but it is laborious getting an accurate comparison. I have read good things about Eisen too. Of the 1440's I was trying to compare, it seemed that Eisen was a good deal cheaper, but cannot confirm that all specs are apples to apples. Not much help I know but...

- Joined

- Sep 10, 2013

- Messages

- 562

Well I’ll say this, Eisen lathes are the exact same OEM equitment as Matt’s machines, at a a higher price. I can tell you that Eisen will not give the personal service that Matt will. I have a PM-932 PDF and a 12x36t which is made in Taiwan, the mill had motor failure which was not Matts fault, but he stepped up and gave me a great deal on a 3 phase 2 hp motor, and now my PM 932 is a vfd controled 3 ph versatile machine. Besides Eisen don’t support these forums like Matt does. I am 99 44/100% satisfied with my PM machines. I have a Grizzly G0704 that is converted to CNC, witch had a ton of problems, and the clausing 100 mk3 that isn’t used much any more because Timken decided to not make the lathe tapered bearings any more. I love that old WWII heavy iron machine. I just didn’t feel like putting 5k into a restored 75 year old machine. I’m a hobbist home machinist. I can do any thing I need for my hobby and my other hobbies they support. If your in business, you don’t need theses light bench machines. So yea I support Matt.

Thanks.

CH

Thanks.

CH