- Joined

- Dec 20, 2012

- Messages

- 9,422

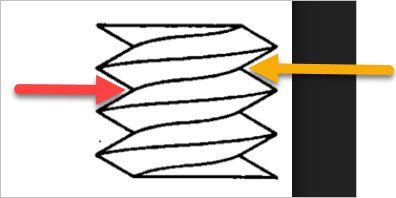

The anvils (1 pointed, 1 V'd) are not fixed in the spindles. They can turn slightly to fit precisely in the thread grooves/points. The key thing is that it is a direct reading (no math or conversions), very handy when you are cutting to tolerance.