Finally gathered up all the basic stuff to start threading, I think... Threading wires, micrometer, thread pitch gauge (U.S) , fish tail gauge, and some tap and dies.

I have watched a lot of videos and read a lot of stuff but this is still a bit intimidating. Equations to figure out size and charts with all kinds of numbers for outer and inner diameters, tool angles...etc

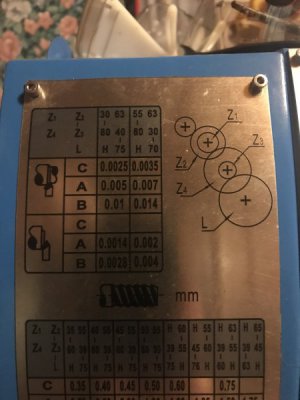

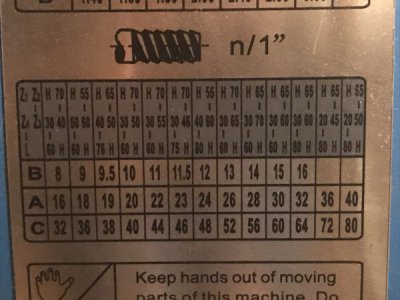

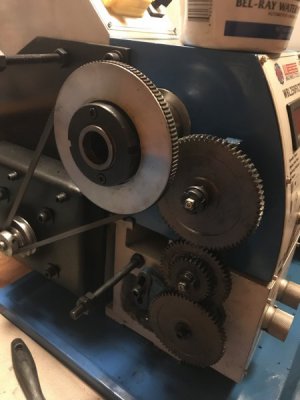

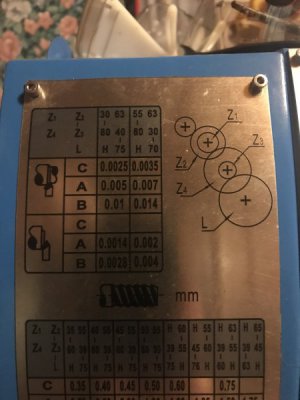

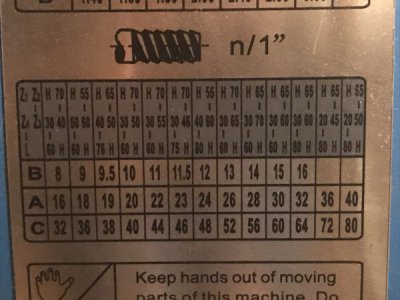

Not sure I understand what the charts on my lathe are telling me exactly as to speed of lathe and gear selection, etc..

Or what kind of threads will it cut as is no change gear..lol

What tool in the arsenal should I choose?

I need some practice and understanding of how to make a matching set of threads, i.e. internal and external fitting threads for a tool height check tool.

Will post progress pics along the way to hopefully help others new to threading.

I have watched a lot of videos and read a lot of stuff but this is still a bit intimidating. Equations to figure out size and charts with all kinds of numbers for outer and inner diameters, tool angles...etc

Not sure I understand what the charts on my lathe are telling me exactly as to speed of lathe and gear selection, etc..

Or what kind of threads will it cut as is no change gear..lol

What tool in the arsenal should I choose?

I need some practice and understanding of how to make a matching set of threads, i.e. internal and external fitting threads for a tool height check tool.

Will post progress pics along the way to hopefully help others new to threading.