- Joined

- Jan 20, 2018

- Messages

- 10

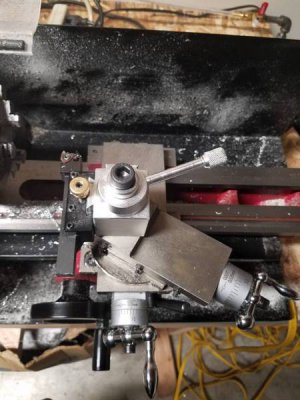

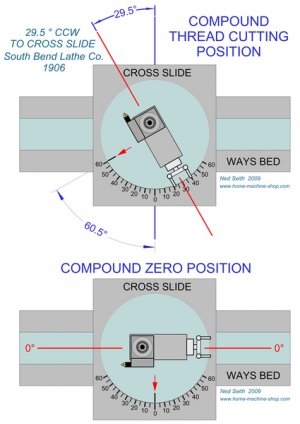

Good evening, I'm new to the forum, and new to machining. I have a HF 7x10 lathe and the small HF mill. I've been working on threading on the lathe, and have so far not been successful. I am currently using a sandvik tool holder with a 16er ag60 insert. Compound is set at 29.5 degrees, and I've given up using the threading dial, and resorted to just backing off and reversing the lathe to restart the thread. I'm still having issues with the insert not following the existing thread. Any help would be greatly appreciated!

Sent from my SM-G935P using Tapatalk

Sent from my SM-G935P using Tapatalk