-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Threading issues

- Thread starter Leadfootsmurf92

- Start date

- Joined

- Apr 28, 2014

- Messages

- 3,590

An aquintance has an HF lathe that he wants me to repair. I'm going to have to see if it's a 7x10 and then I'm gong to figure out how

the bloody compound is laid out just to satisfy my curiosity...

I would have thought that it was scribed to some sort of a standard. but then again....

BTW, just for the record, 7/8"-32 is not a 'fun' thread to start out on. Just in case you were wondering...

There's no 'wiggle' room and of course one always messes up on the last pass....

the bloody compound is laid out just to satisfy my curiosity...

I would have thought that it was scribed to some sort of a standard. but then again....

BTW, just for the record, 7/8"-32 is not a 'fun' thread to start out on. Just in case you were wondering...

There's no 'wiggle' room and of course one always messes up on the last pass....

- Joined

- May 10, 2017

- Messages

- 1,199

BTW, just for the record, 7/8"-32 is not a 'fun' thread to start out on. Just in case you were wondering...

There's no 'wiggle' room and of course one always messes up on the last pass....

I’ve felt that “last pass “ pain several times.

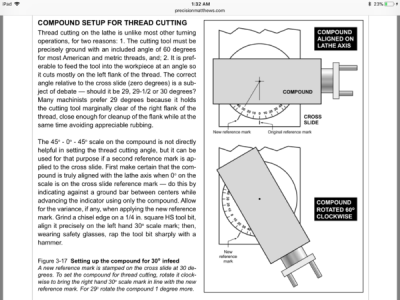

Make sure you check the front of the cross slide (facing the head stock). Most lathes have more than one spot to check angles.Ok that makes sense. But my angle marks only go to 45, so I need to use a different method to calculate the angle?

Sent from my SM-G935P using Tapatalk

- Joined

- May 10, 2014

- Messages

- 819

This is a common problem for folks starting out. I had the same issue. The compound scale did not go far enough. I made a simple jig to set the compound. See my post #11 in this earlier thread.

Threading issue

Threading issue

- Joined

- Jan 20, 2018

- Messages

- 10

Thank you everyone for all of your help! I am going to adjust my compound tonight after work and try again, hopefully with better results!

Sent from my SM-G935P using Tapatalk

Sent from my SM-G935P using Tapatalk

- Joined

- Feb 1, 2015

- Messages

- 9,570

Here is my solution for setting the 29.5º angle for threading. https://www.hobby-machinist.com/threads/29-5-deg-angle-tool-for-lathe.34541/ Another way would be to use a draftsman's 30-60-90 triangle to set the compound to set the angle between the side of the compound and the face of the chuck and just bump it slightly to reduce to less than 30º. The actual angle isn't critical as long as it isn't more than 30º.

- Joined

- Jun 7, 2013

- Messages

- 10,070

I was taught to use a 30 degree setting of the compound for threading in my high school machine shop class by the teacher who had taught in the apprentice school at Mare Island Navy Yard; the trick for cleaning up the backside of the thread was to slightly drag on the carriage handwheel on the last cleanup cut; this was also observed by all the machinists that I knew in the shop where I apprenticed.

In the instance of the lathe with no markings shown in this thread, I would establish the correct angle with a protractor or whatever means is at hand, then scribe a line on the cross slide against the compound for future reference.

In the instance of the lathe with no markings shown in this thread, I would establish the correct angle with a protractor or whatever means is at hand, then scribe a line on the cross slide against the compound for future reference.

- Joined

- Aug 15, 2013

- Messages

- 2,109

Concerning making a jig or template to quickly set the compound angle for threading, I kept saying I was going to make one but never got a round tuit. Instead, after using a protractor about a dozen times to set the angle (and being efficient at physical activity, which some who know me have erroneously called "lazy"), I did the same as benmychree and scribed a reference mark on the cross slide. But, my compound is slightly elevated above cross slide, so I marked the cross slide at the zero degrees mark on the compound degree scale when it was set for threading, much like the factory mark on the PM1236 in Z2V's post above.

Tom

Tom

Last edited: