- Joined

- Jan 25, 2018

- Messages

- 22

Hi All,

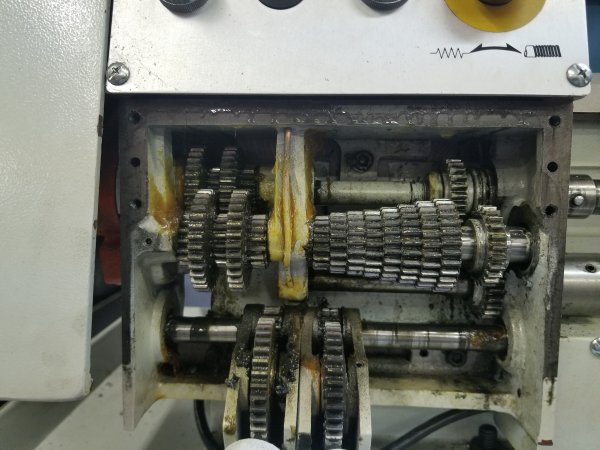

Recently I've noticed an exceptional amount of end play in my threading leadscrew, I believe this is what is causing unevenness in my thread thickness. The manual doesn't show how to adjust the endplay and I really don't want to cause more damage than good. Has anyone had to make adjustments on the endplay and if so what is the best way to do it.

Thanks in advance,

Mike

Recently I've noticed an exceptional amount of end play in my threading leadscrew, I believe this is what is causing unevenness in my thread thickness. The manual doesn't show how to adjust the endplay and I really don't want to cause more damage than good. Has anyone had to make adjustments on the endplay and if so what is the best way to do it.

Thanks in advance,

Mike