- Joined

- Sep 22, 2010

- Messages

- 7,223

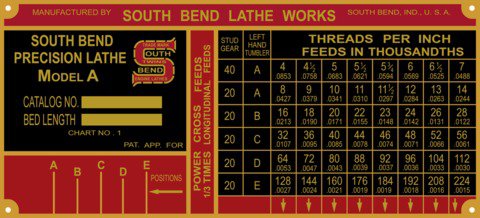

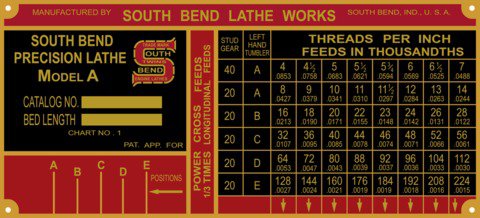

THREADS PER INCH

FEEDS IN THOUSANDTHS

Now look at the first row, third column. It shows:

4

.0853

The 4 is the threads per inch it will cut using the half-nuts when the gears are set for that pitch.

The .0853 is the cut it will make using the clutch (and NOT the half-nuts) for each revolution of the spindle. It's about a third the rate of the

Now look at the 40 TPI. Since it's ten times 4, one might expect the feed rate for turning to be .0085, and it is.

The upper number is the feed rate in threads per inch using the half-nuts, and the lower number is the feed rate using the clutch. If you're going to be threading, install the gears to effect that thread. If you're turning, look on the chart for the thickness of the chip* you want to remove, and set up the gears as indicated on the chart, but use the clutch and not the half nuts.

Example (using the chart):

If you want to make your chips .003" thick (a good place for steel), look for the lower number citing that size. It's under the 112 tpi. Arrange your gears to cut a 112 pitch (tpi), and use the clutch to get a feed rate of .003".

*Here's what I mean by 'thickness of the chip':

Imagine a 1" round plastic rod in your chuck, sticking out about two inches. The tailstock is not used, just the plastic stub sticking out of the chuck. (I'm using plastic because it's easier to cut in my mind)

Now, using the crossfeed, run your cutter up to the plastic rod until it just touches, then move the carriage to the right, so the cutter clears the work, and crank it in another .250" (1/4").

With the gears set to cut a thread pitch of 112 (using this chart), turn on the lathe, engage the half-nuts, let the cutter take a cut for one or two revolutions. Remove the chip and measure it.

Since you ran the crossfeed in .250", the chip will be 1/4" WIDE and .008" THICK. (The .008 comes from 1 divided by 112).

Now disengage the half nut, and do it again using the clutch. THIS chip will still be 1/4" wide, but only .003" thick, (because of the different ratio via the gears inside the apron).

The feed RATE will be determined by trial and error using your cutter, the material you're cutting, and the power of your lathe. The width of chip will be determined by what your lathe will handle at that feed rate.