Re: Tight compound on round-dial 10ee

I took apart the cross slide and compound on my 10ee. Turning the dial for the compound is tough. I can only find one screw to adjust the gibs and it only turns about a quarter turn. It doesn't seem to make a difference. I thought most gibs have a locking scrandover the back and an adjusting screw up front. All I see is a front screw. I'm hesitant to whack the wedge out with a mallet. Any insights here?

Thanks.

Hi Christian,

The compound gib just has the one screw. It works against a slot in the gib, rather than pushing against the end of the gib, like the cross-slide gib adjustment screws.

You don't want the compound or the cross-slide to be super easy to turn. If they are, they're probably too loose and will deflect under pressure from the cutting forces. Your gib is probably gunked up from too many years with too little maintenance.

If you can't get the gib to move with a screwdriver in the hole in the end-plate, remove the 3 socket head screws and rotate the plate so that you can get a larger screwdriver in the adjusting screw, that should give you enough leverage to be able to loosen the gib. The adjuster is a right-hand thread, so counterclockwise rotation will loosen it. If that's still not working, rotate the screw clockwise as far as it will go, then use a small brass rod to tap the other end of the gib towards the screw. (You can see the space for the gib on the right side of the dovetail.) That should allow you to back the screw of a little more. Keep doing that until you get the gib loose. Then you can unthread the feed screw, complete with the dial and end-plate. The top slide will then slide off the rear of the compound, leaving just the bronze nut. Check for any burrs on the gib or the ways; remove any that you find with a fine stone.

You should back the compound screw out and slide the top off periodically so that you can clean and oil the ways and the screw. Also put a drop of oil on the thrust bearing.

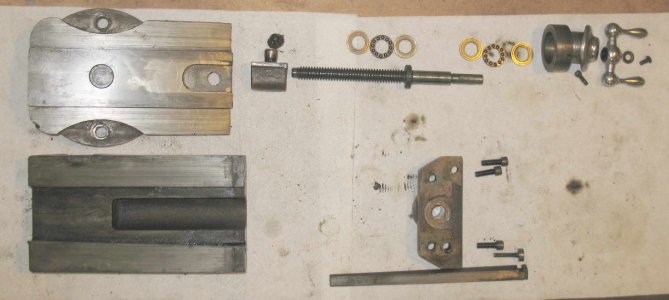

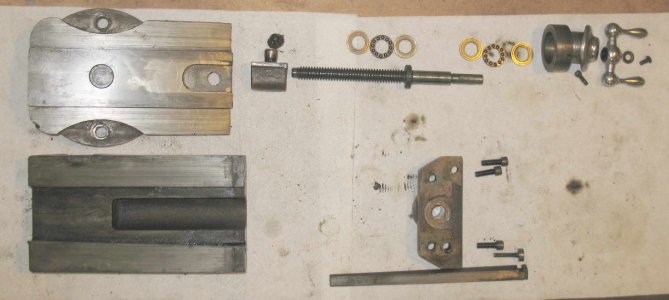

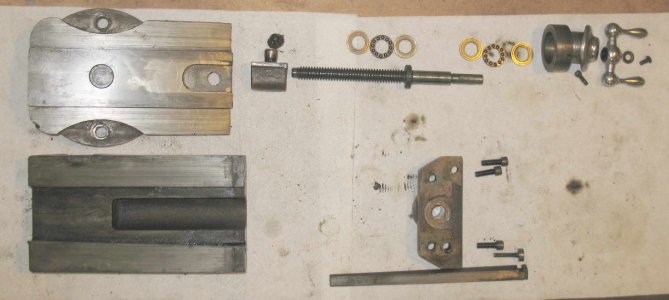

Here's what parts for the round-dial compound look like:

Cal

Cal