- Joined

- Jan 10, 2016

- Messages

- 29

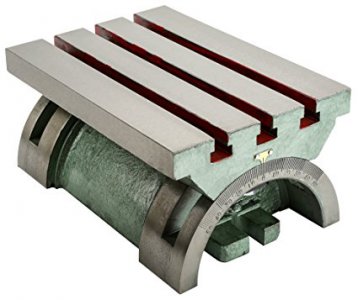

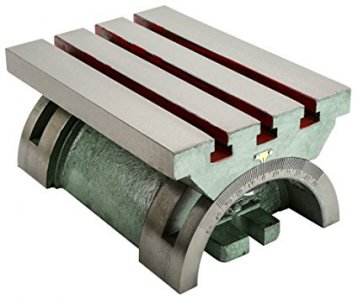

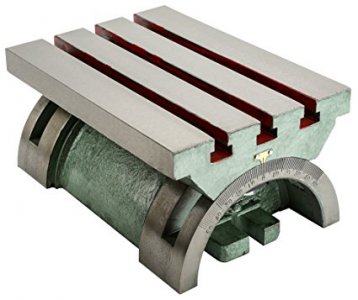

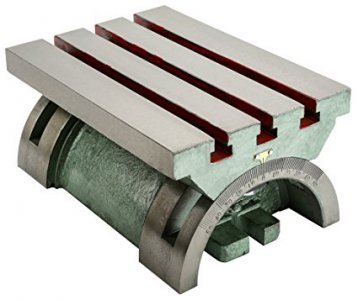

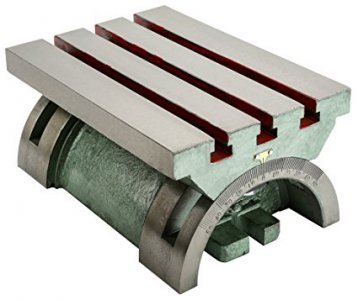

I am thinking to get a tilting table size ~ 7x5" my question is how sturdy are they for mini mill use (I have a LMS 3990 ) . There are several models available - I wonder if you can share experience with them / relative pros and cons of each model

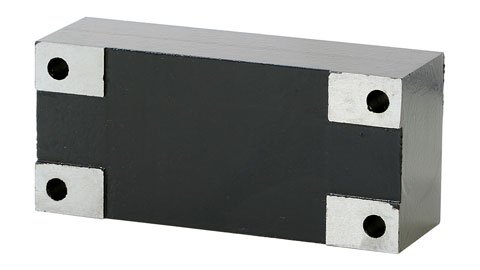

1. Grizzly G5758

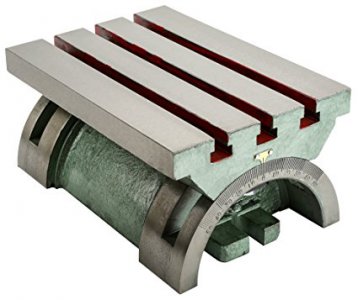

2. Ajax industry

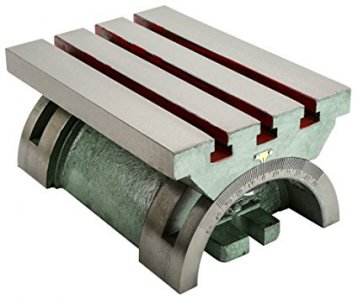

Grizzly G9302

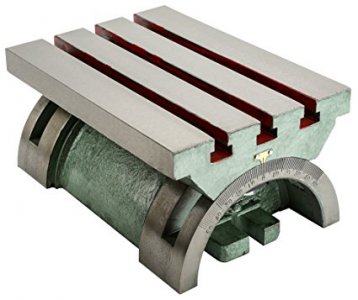

Grizzly G9301

1. Grizzly G5758

2. Ajax industry

Grizzly G9302

Grizzly G9301