- Joined

- Feb 27, 2014

- Messages

- 2,128

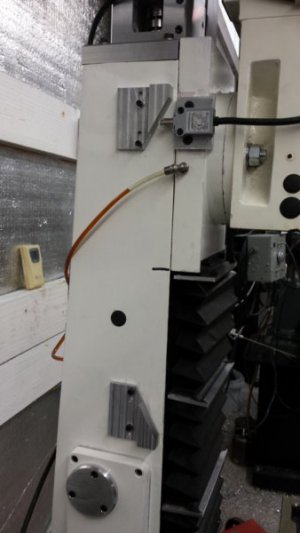

Well the onshot oil pump that came with the PM45M-CNC quit pumping oil this week. I was never really happy with it other than it seemed to work nothing seems to have failed due to poor lubrication. My two biggest concerns were that you had to manually turn it on and off. If you turned it on and then forgot to turn it off 30 seconds later then it would just merrily pump all the oil in the reservoir onto the ground. I have tested this process several times  . Another issue is that the Z-Axis ways are not included in the system. Instead I have two cups that I fill up before each job. It has a very simple manifold and no check valves so I have not idea how much oil is getting to the z-axis ball nuts (if they are ball nuts, I am not sure).

. Another issue is that the Z-Axis ways are not included in the system. Instead I have two cups that I fill up before each job. It has a very simple manifold and no check valves so I have not idea how much oil is getting to the z-axis ball nuts (if they are ball nuts, I am not sure).

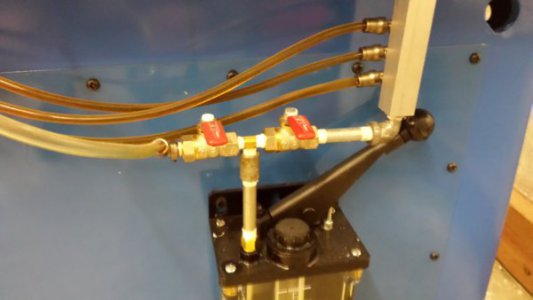

So, my project is to replace and upgrade. The current pump is 220VAC and I can find several on ebay at affordable prices that have a configurable duty cycle to avoid the "Oil-on-the-Floor" syndrome. Anyone with a recommendation or advice on how to pick the best pump?

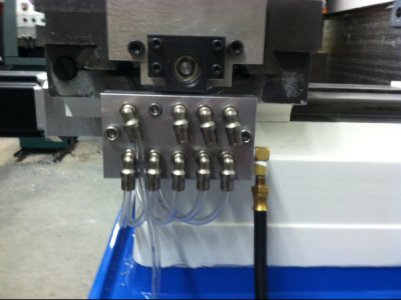

Next I want to add a manifold with needle valves and Ball Check Valves so at least the oil going to the Z-Axis will not drain down between cycles. All this seems straightforward but would love to see some pictures of what other people have done. Another area for improvement is that there is only one oil line going to the X&Y axis and Ball-Nuts. There must be a splitter or manifold up under the table. How hard is it to remove the table and potentially bring all the lines out separately? Last question (for now) Is there any reason I can't route a couple of oil lines to replace the two oil cups on the Z-Axis ways?

Thanks in advance for any ideas or guidance on this.

So, my project is to replace and upgrade. The current pump is 220VAC and I can find several on ebay at affordable prices that have a configurable duty cycle to avoid the "Oil-on-the-Floor" syndrome. Anyone with a recommendation or advice on how to pick the best pump?

Next I want to add a manifold with needle valves and Ball Check Valves so at least the oil going to the Z-Axis will not drain down between cycles. All this seems straightforward but would love to see some pictures of what other people have done. Another area for improvement is that there is only one oil line going to the X&Y axis and Ball-Nuts. There must be a splitter or manifold up under the table. How hard is it to remove the table and potentially bring all the lines out separately? Last question (for now) Is there any reason I can't route a couple of oil lines to replace the two oil cups on the Z-Axis ways?

Thanks in advance for any ideas or guidance on this.