- Joined

- Aug 23, 2014

- Messages

- 214

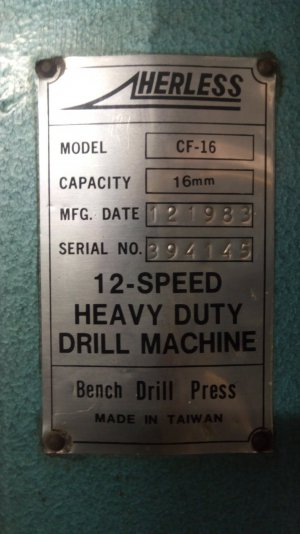

Drill press getting a long overdue birthday. It has some serious table droop, the lift mechanism needs a proper seeing to and the column could do with a clean up.

We'll see what else crops up.

First step, set up the portable gantry crane and remove the drill head.

We'll see what else crops up.

First step, set up the portable gantry crane and remove the drill head.